14.1. Introduction and Overview¶

14.1.1. Historical Background and Description of the Physical Model¶

The PLUTO2 module calculates the post‑failure fuel motion and sodium voiding in subassemblies experiencing an overpower condition leading to significant fuel melting, fuel‑pin failures and fuel ejection into unvoided or partially voided coolant channels. The degree of fuel‑pin disruption is limited to cladding ruptures through which molten fuel can be ejected into the coolant channels. Thus, this model will be appropriate for treating the early post‑pin‑failure phase of higher ramp rate transient overpower (TOP) accidents and the entire post‑failure phase of lower ramp rate TOPs if no complete pin disintegration or extensive cladding melting occurs. Of additional importance is the module’s application to the early post‑pin‑failure fuel motion and sodium voiding in unvoided or partially voided subassemblies experiencing a Loss‑of‑Flow driven TOP (LOF’d’TOP). Once complete pin disintegration, high fuel vapor pressures, or molten cladding motion have to be considered, a switch to the LEVITATE module, which is designed to treat these phenomena, is made. This compatibility between PLUTO2 and LEVITATE is important for a consistent continuation of the analysis of the transient. This compatibility did not exist between the corresponding SAS3D modules SAS/FCI [14‑1] and SLUMPY [14-2] which could never be used sequentially to treat the same fuel pin.

The PLUTO2 module can be used in all situations for which the SAS/FCI module of SAS3D was used. Moreover, the PLUTO2 fuel pins can fail into partially voided coolant channels, which was not possible with SAS/FCI. The models in PLUTO2 are considerably more mechanistic than those used in SAS/FCI. For example, fuel motion in SAS/FCI was largely treated with a lumped parameter approach, whereas PLUTO2 has one‑dimensional models of the fuel motion inside the pins and in the coolant channels. Moreover, PLUTO2 treats phenomena that were not addressed in SAS/FCI such as continuous molten fuel flow regimes and the plateout of freezing fuel.

The PLUTO2 module is an outgrowth of the earlier PLUTO code [14‑3, 14‑4] which has been successfully used to simulate the early sodium voiding and fuel motion in TOP experiments [14‑5, 14‑6]. Therefore, the basic PLUTO concept has been retained in PLUTO2. However, as mentioned above, PLUTO2 is also designed to analyze the longer‑term phenomena in mild TOPs and the early phases of LOF’d’TOPs. Moreover, PLUTO2 has an Eulerian hydrodynamic treatment which eliminates most of the cumbersome rezoning that was necessary in the Lagrangian PLUTO code. The Eulerian treatment has allowed the incorporation of axial cladding rupture propagation, fuel plateout, and variable cross section flow. Furthermore, PLUTO2 is considerably more economical to run than PLUTO; this is of importance for a module of a whole‑core analysis code.

The PLUTO2 (and LEVITATE) coolant‑channel treatment considers the entire subassembly cross section with all associated cladding and structure although the treatment is still one‑dimensional. This is somewhat different from the concept that is used in the pre‑fuel motion phase in SAS4A. The latter considers the coolant flow area, cladding and structure associated with only one pin.

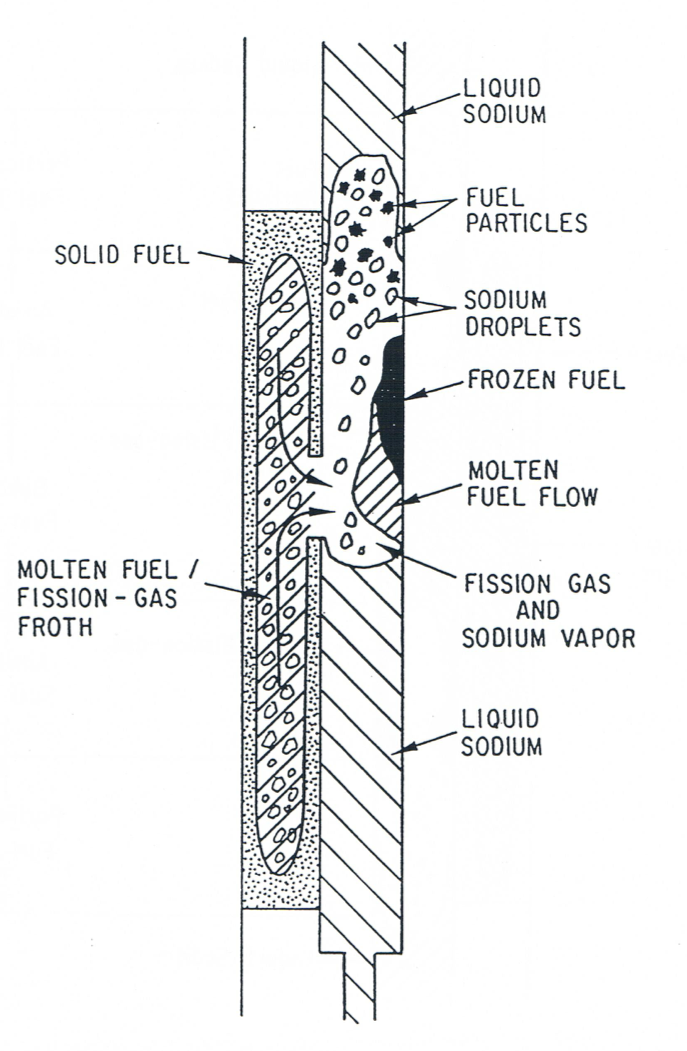

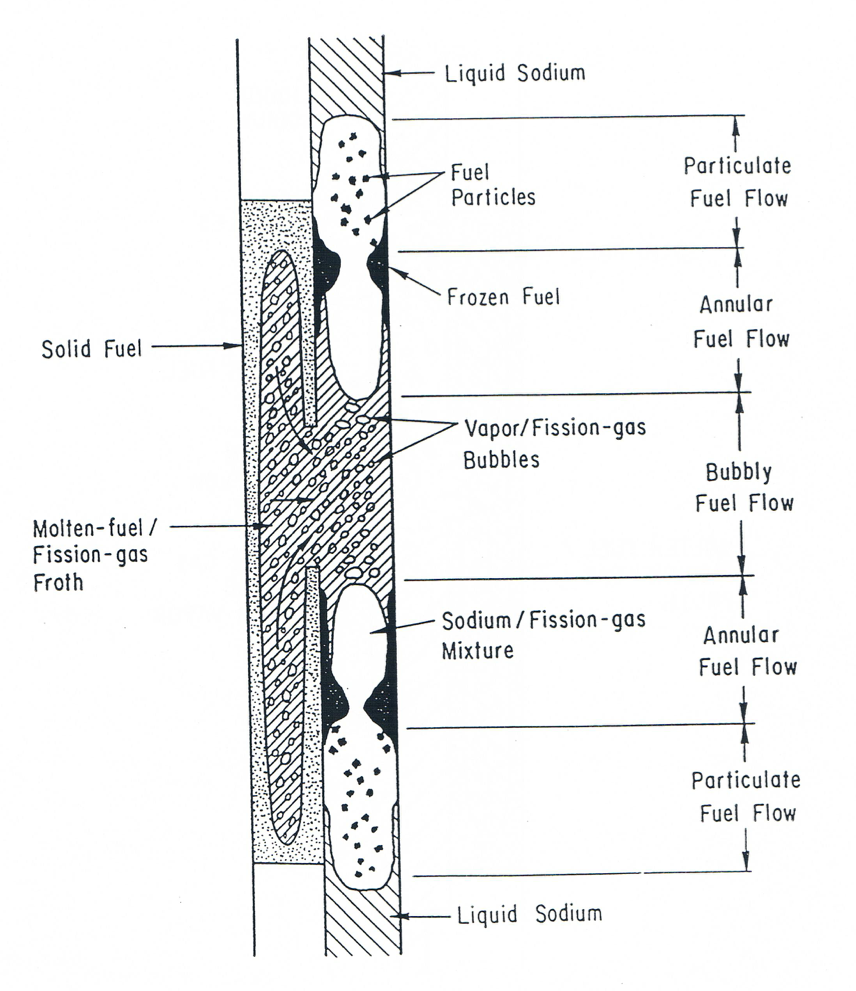

Schematics of the PLUTO2 model when used for a mild TOP calculation and for a LOF’d’TOP condition are shown in Figure 14.1.1 and Figure 14.1.2, respectively. These schematics are for a single pin with a coolant channel that can belong to one or more pins. Although the PLUTO2 channel treatment is one‑dimensional (i.e., there is a common treatment of all subchannels), not all of the fuel pins in a subassembly have to fail simultaneously. A number of the pins, as specified by input, can remain intact. A treatment of the delayed failure of these pins is not yet operational. In cases that assume that only some of the pins in a subassembly fail, the fuel and gas ejection from these failed pins will be added to all coolant subchannels since all subchannels in a subassembly are treated alike. This has prompted the use of the above‑mentioned concept in PLUTO2 in which the basic channel cell has a cross section equal to the entire coolant flow area in a subassembly.

The PLUTO2 model addresses three major modeling areas pertinent to the post‑pin‑failure behavior. The first area is the in‑pin fuel motion toward a cladding rupture, the second is the fuel and gas ejection through the cladding rupture, and the third is the multi‑component, multi‑phase hydrodynamics treatment in the coolant channel.

The basic assumption for the in‑pin motion is the treatment of the molten fuel region inside the pin (see Figure 14.1.1 and Figure 14.1.2) as a pressurized cavity containing fuel and fission gas, which flow toward a cladding rupture. This general concept was already used in SAS/FCI, PLUTO, and EPIC [14‑7, 14‑8]. The key PLUTO2 features in the modeling of the in‑pin flow are:

A1) Treatment of the two‑phase, two‑component flow as a compressible homogeneous flow with variable flow cross section and strong mass sinks (due to fuel ejection) and mass sources (due to the addition of melting fuel).

A2) Modeling of the radial and axial growth of the molten fuel cavity due to additional fuel melt‑in determined by a heat‑transfer calculation in the solid fuel annulus which is performed by subroutine PLHTR.

A3) The treatment of two types of fission‑gas bubbles in the molten cavity. These are the large fission‑gas bubbles on the grain boundaries which are assumed to act like free gas and exert pressure in the molten cavity and very small intragranular bubbles which do not affect the cavity pressure directly because they are assumed to be totally constrained by surface tension. However, these small bubbles can coalesce into large bubbles and thus contribute to the cavity pressurization in a delayed fashion. In the code, the rate of coalescence is controlled by an input time constant. Up to the time of pin failure, when PLUTO2 is initiated, the relative fractions of these two types of gas bubbles in the solid fuel and molten fuel cavity are calculated by DEFORM. DEFORM has the same two‑bubble fission‑gas treatment and uses the same input grain‑boundary gas fraction and time constant for small bubble coalescence. Once PLUTO2 is active, additional fuel can melt into the cavity which brings fission gas with it. The total amount of fission gas in the melting fuel node is known from the steady‑state DEFORM calculation. In the solid fuel, the DEFORM calculation tracks grain boundary gas (large bubbles) and intragranular gas (small bubbles) separately. The input fraction (FIFNGB) should roughly correspond to the fraction of gas on the grain boundaries in the solid fuel as determined from post‑irradiation examinations of fuel pins.

A4) A simple fuel vapor pressure calculation which is based on the radially averaged temperature in a cavity node is performed. The fuel vapor pressure and the fission‑gas pressure are assumed to be additive. A better fuel vapor pressure calculation would be based on the maximum fuel temperature in a node. However, computing the latter in a moving fluid is difficult. Also, it is not clear that any significant radial temperature gradients remain present after the onset of fuel motion. This problem will be addressed in future SAS4A work.

The fuel ejection from the pins is based on the assumption that the cavity pressure in the node behind the cladding rupture of the failed pins equilibrates instantaneously with the coolant channel pressure at the same elevation by ejecting appropriate amounts of fuel and gas. The latter are ejected with the same volume ratio as present in the cavity nodes. If the pressure in the coolant channel becomes temporarily higher than the pressure in the failed cavity nodes, the fuel and gas ejection is halted. Backflow of fuel, gas or sodium into the pins is not allowed. Two items concerning pin failure coherency and the axial pin‑failure propagation are of importance:

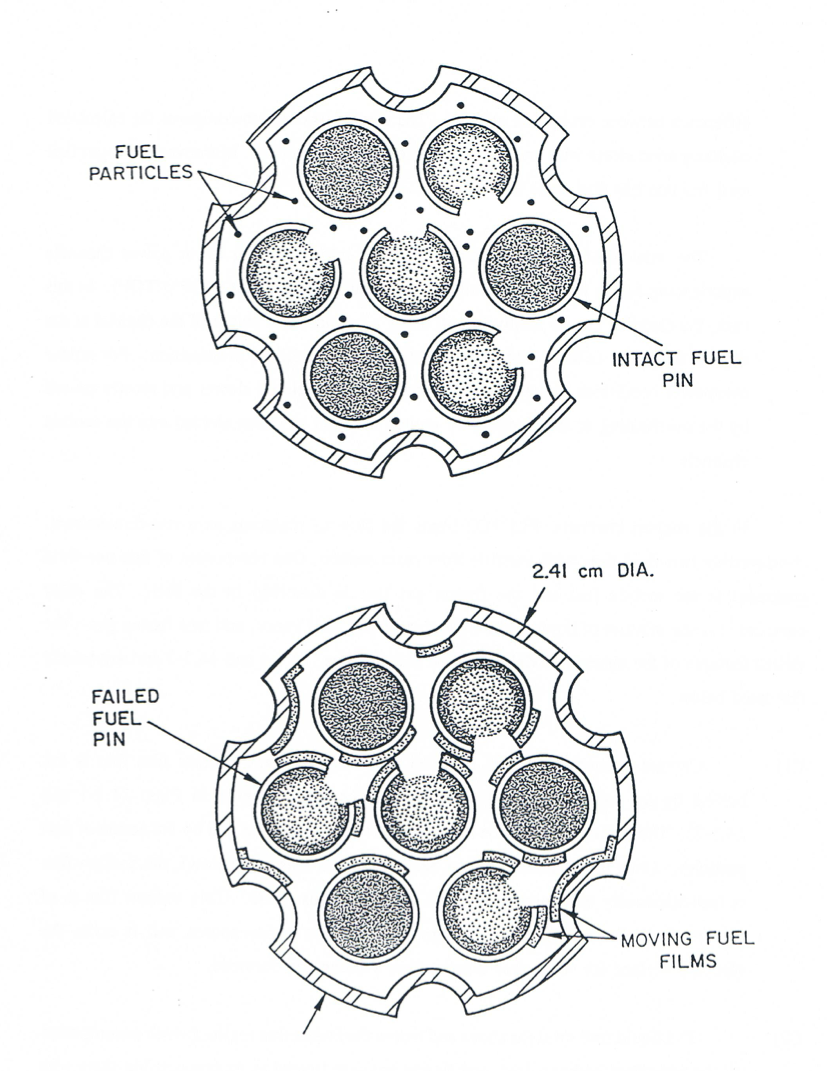

B1) There is an option to fail only some of the pins in a subassembly. The other pins remain intact. This option is relevant for mild TOPs. Because of the common one‑dimensional treatment of all subchannels, this requires that the failed pins are reasonably well distributed over the subassembly cross section (see Figure 14.1.3). A problem with this option is that LEVITATE cannot be switched on after PLUTO2 because LEVITATE assumes that all pins in a subassembly are failed.

B2) The cladding failures can enlarge axially; this is also referred to as axial pin‑failure propagation. There is a nonmechanistic pin‑failure propagation option available which is keyed on input fuel melt fraction, cladding temperature, and required pressure difference between cavity and channel. The mechanistic option compares the calculated cladding hoop stress with an ultimate tensile strength function. Moreover, an input fuel melt fraction has also to be exceeded.

The axial pin‑failure propagation is of key importance for lower power channels experiencing a high overpower condition due to an LOF accident (LOF’d’TOP). In this case, the cladding can be relatively soft along a considerable length of the channel at the time of the initial failure. This may lead to rapid axial failure propagation. For milder overpower conditions, the axial failure propagation would be slower and mostly caused by the overheating of the cladding by molten fuel that has been ejected into the coolant channels.

Figure 14.1.1 PLUTO2 Schematic for Transient Overpower Conditions¶

Figure 14.1.2 PLUTO2 Schematic for Loss of Flow Driven Transient Overpower Conditions¶

Figure 14.1.3 Illustration of Particulate Fuel Flow Regions (Upper Figure) and Partial Annular Fuel Flow Regime (Lower Figure) for a Seven-Pin Bundle in Which Only Four Pins Are Assumed to Have Failed¶

In the coolant channels, PLUTO2 treats the flow of materials as a one-dimensional, compressible two‑fluid flow with variable flow cross section. One component of this two‑fluid treatment is the mobile fuel and the fission gas that is dissolved in the fuel. The other component is the mixture of liquid sodium, sodium vapor, fuel vapor, and free fission gas. The salient features of the channel modeling can be seen in Figure 14.1.1 and Figure 14.1.2 and are briefly discussed below.

C1) Coolant channel boiling is modeled by treating a static sodium film that is left behind by the expelled coolant slugs (see upper voided region in Figure 14.1.1 and Figure 14.1.2). The sodium film can be entrained by vapor streaming and by the action of fuel particles. Once the fuel flow regime becomes continuous (see below), the sodium film is instantaneously entrained as droplets in the gaseous phase. This sodium film is of importance because it provides a significant sodium vapor source and it cools the cladding surface for some time after sodium voiding has occurred.

C2) The liquid sodium slugs above and below the interaction region (which encompasses all the two‑phase sodium, fuel, and fission gas) are treated as incompressible slugs with variable flow cross section. However, during the first few milliseconds after failure, an acoustic approximation is made to determine the slug interface velocities.

C3) Three different fuel flow regimes are treated in PLUTO2: particulate, partially or fully annular, and bubbly. The flow regime selection is mainly keyed to the liquid sodium fraction and to the channel fuel volume fraction.

The fuel motion in TOP accidents has been traditionally modeled as a particulate fuel suspension in a two‑phase sodium/fission‑gas mixture. However, the breakup of fuel into droplets or particles is likely only when the liquid sodium fraction is fairly high. From TREAT experiments, it can be concluded that continuous molten fuel flow regimes exist in voided regions. In PLUTO2, continuous fuel flow regimes are, therefore, considered in addition to the particulate flow regime. The treatment of a partially annular fuel flow regime is not a common approach but has been prompted by the notion that a relatively small amount of molten fuel in a voided channel will not cover the entire cladding and structure perimeter, but will rather behave like a single or multiple rivulet flow. For higher fuel fractions, a complete annular fuel flow regime is assumed and for an even higher fuel volume fraction, a bubbly fuel flow is modeled. Figure 14.1.3 illustrates the particulate and partially annular flow regime models for a seven‑pin TREAT test bundle for the case in which only a certain fraction of the pins has failed. For the particulate or bubbly fuel flows, the fuel is simply uniformly distributed in all subchannels. For the partially annular flow, the fuel mass is assumed to be distributed between the pin cladding and structure in proportion to the cladding‑to‑structure surface area ratio. The cladding of all failed and unfailed pins is assumed to be covered by equal amounts of fuel film with equal film thickness. The fraction of the cladding perimeters covered by the fuel films is dependent on the fuel volume fraction and the input constant CIANIN. Where this fuel is exactly located on the pin perimeters is not relevant since there is no azimuthal cladding temperature distribution calculated. The fraction of the fuel covering the structure is of considerable importance in small bundles. Once frozen fuel crusts are generated (see below), they are also distributed in the same manner. Once the fuel fraction is high enough to lead to a fully annular flow, all cladding and structure in a given node is covered by the fuel films. The fuel flow regimes will be discussed in more detail in Section 14.4.2. Figure 14.4.1, which is shown later in Section 14.4, illustrates the fuel flow regimes in more detail for an equivalent cylindrical geometry.

Modeling these different fuel flow regimes explicitly has the advan‑tage that one has all interaction areas for heat, mass, and momentum transfer readily available.

C4) Frozen fuel plateout is treated in PLUTO2 because there is over‑whelming evidence from in‑pile and out‑of‑pile experiments that fuel freezing and plateout are key phenomena. In PLUTO2, only fuel in the continuous flow regime can plate out on cladding and structure upon fuel freezing. The fuel particles are not allowed to stick to cladding and structure because the fuel particles are assumed to have a solid shell due to their interaction with liquid sodium.

The modeling of the fuel plateout in PLUTO2 can either be of the bulk‑freezing type or conduction‑limited type. This is controlled by input parameter CIFUFZ, which also allows intermediate modes. Frozen fuel crusts can also become mobile after remelting. In addition, frozen fuel crusts are released into the moving fuel stream if the underlying clad or structure becomes significantly molten.

C5) The Fuel‑Coolant Interaction (FCI) treatment depends on the fuel flow regime. In the particulate flow regime, the FCI treatment is largely based on the Cho‑Wright approach [14‑9] which considers the heat flow resistance in the fuel particles and ignores the resistance of liquid sodium. Moreover, the resistance due to vapor blanketing is treated in a parametric fashion in PLUTO2. In the code, separate FCI calculations are done for every numerical cell, whereas the Cho‑Wright model is a lumped‑parameter approach. Of importance for the FCI treatment in PLUTO2 is also the treatment of the slip between fuel and liquid sodium which mitigates the strength of the FCI’s.

In the annular fuel flow regimes in PLUTO2, the convective heat transfer between the hot fuel film and/or fuel crusts and the two‑phase sodium/fission‑gas mixture is considered. Since the fuel surface area for the annular flow is significantly smaller than that for the particulate flow, this type of FCI is much milder.

In the bubbly fuel flow regime high heat‑transfer rates between fuel and liquid sodium are possible, but the bubbly fuel flow regime is usually generated at an axial elevation where no liquid sodium is present. The penetration of liquid sodium into a bubbly fuel flow regime is also unlikely in the one‑dimensional PLUTO2 because the cladding near a node with bubbly flow is usually too hot to allow reentry of liquid sodium.

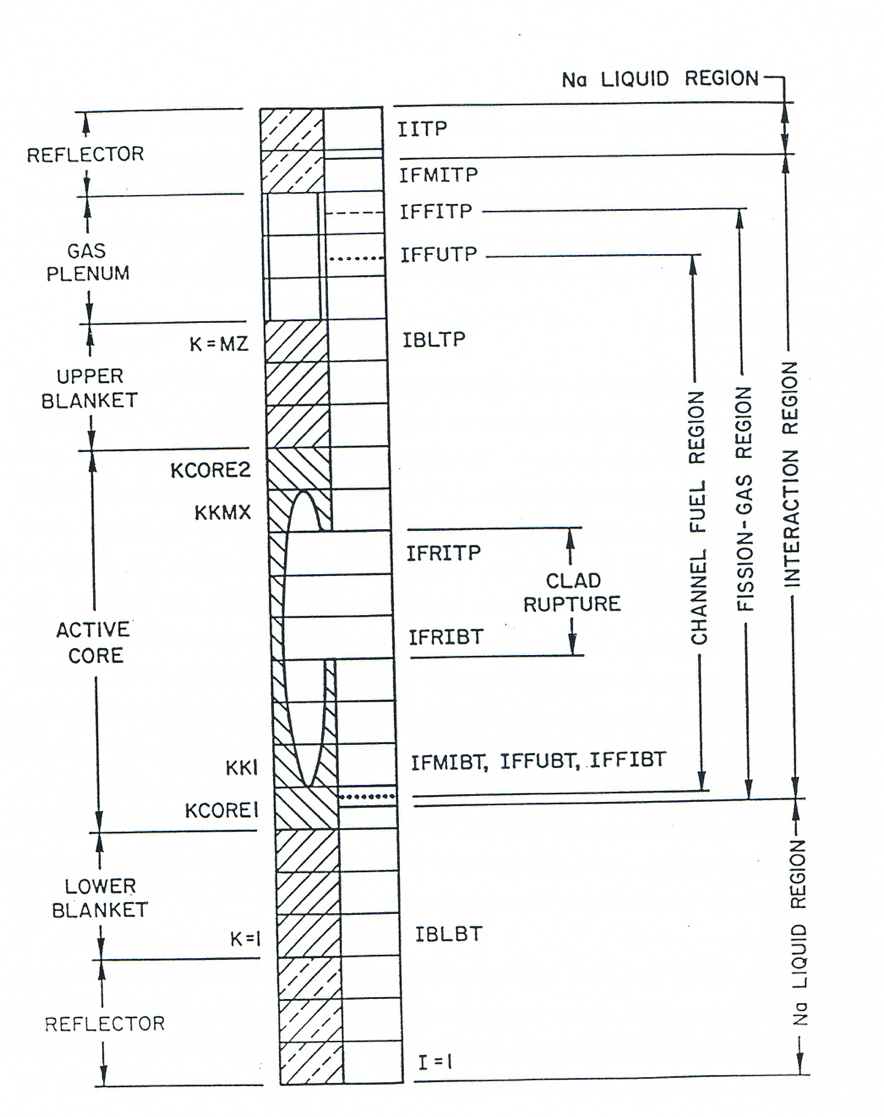

The numerical grids on which the hydrodynamics equations are solved are shown in Figure 14.1.4. The stationary Eulerian grid in the molten pin cavity is aligned with the stationary Eulerian grid in the coolant channel. The cavity grid can expand continuously in the radial direction due to fuel melt‑in and stepwise (by whole cells) in the axial direction. The grid on which the reactivity calculations are done covers the pin and blankets and the adjacent coolant channel cells from K = 1 to K = MZ. Outside the molten cavity region, this grid is also subdivided radially for the heat‑transfer calculation in the solid fuel and cladding. The interaction region in the coolant channel can expand or contract continuously in the axial direction, which requires a partially Lagrangian treatment for the edge cells of the interaction region. The channel fuel region and the fission‑gas region also expand or contract continuously in the axial direction. However, when they have moved into a new cell, the fuel or fission gas is assumed to be homogeneously distributed in that cell for calculating the pressure, heat transfer, momentum change, and reactivity. On the mesh grids above and below the interaction region, only the liquid sodium temperatures are calculated. The momentum change of the liquid sodium slugs is calculated in an integral fashion.

The current status of the PLUTO2 validation and its future validation needs are discussed in the SAS4A Validation and Verification Plan [14‑10]. Here only an enumeration of the integral validation efforts already performed will be given. As mentioned earlier, the PLUTO code has been successfully used to simulate the early sodium voiding and fuel motion in two in‑pile TOP experiments [14‑5, 14‑6]. PLUTO2 comparison calculations with PLUTO showed good agreement for the early fuel motion and sodium voiding [14‑11]. An intercode comparison with the EPIC code for LOF’d’TOP conditions showed that the two codes compare rather well when several of the advanced features in PLUTO2, such as fuel flow regimes and fuel plateout, are switched off [14‑12]. PLUTO2 was also used in the EEC‑WAC TOP comparative exercise [14‑20]. Because its advanced features were active in this comparison exercise, the PLUTO2 results differed considerably from those calculated with simpler models.

A reasonably good post‑test simulation of the major flow event in the H6 50 ¢/s TOP TREAT test [14‑13] was achieved through input parameter adjustments [14‑6]. However, some uncertainty with regard to the mode of the FCI observed in this test could not be resolved. A good post‑test simulation of the L8 LOF’d’TOP TREAT Test [14‑14, 14‑15, 14‑12] was also achieved after introduction of a model for frozen fuel crust release from molten cladding. This was prompted by a pre‑test analysis which underpredicted the fuel dispersal [14-16]. Other pretest predictions with PLUTO2 were made for the AX1 $3/s TOP test using carbide fuel [14‑17], the W2 10 ¢/s TOP test in the ETR [14‑18], and the 37‑pin bundle P4 pin‑failure propagation test in ETR [14‑19]. The prediction for the AX1 test was quite reasonable, whereas the prediction for W2 suffered from the assumption of too coherent pin failures. The PLUTO2 P4 pretest analysis predicted a complete sweepout of the fuel ejected from the three fuel canisters used in this test, whereas the experiment led to very little sweepout and a sizable frozen fuel blockage. Possible explanations of the observed behavior include sodium bypass effects in a large bundle or the fuel canister ejecting the fuel more violently than the fuel pins in TOP tests.

Figure 14.1.4 Axial Mesh Cells Used in the Pin and the Coolant Channel for the Numerical Solution of Conservation Equations. Also Shown Are the Different Component Regions in the Channel¶

14.1.2. Overview of the Program Flow¶

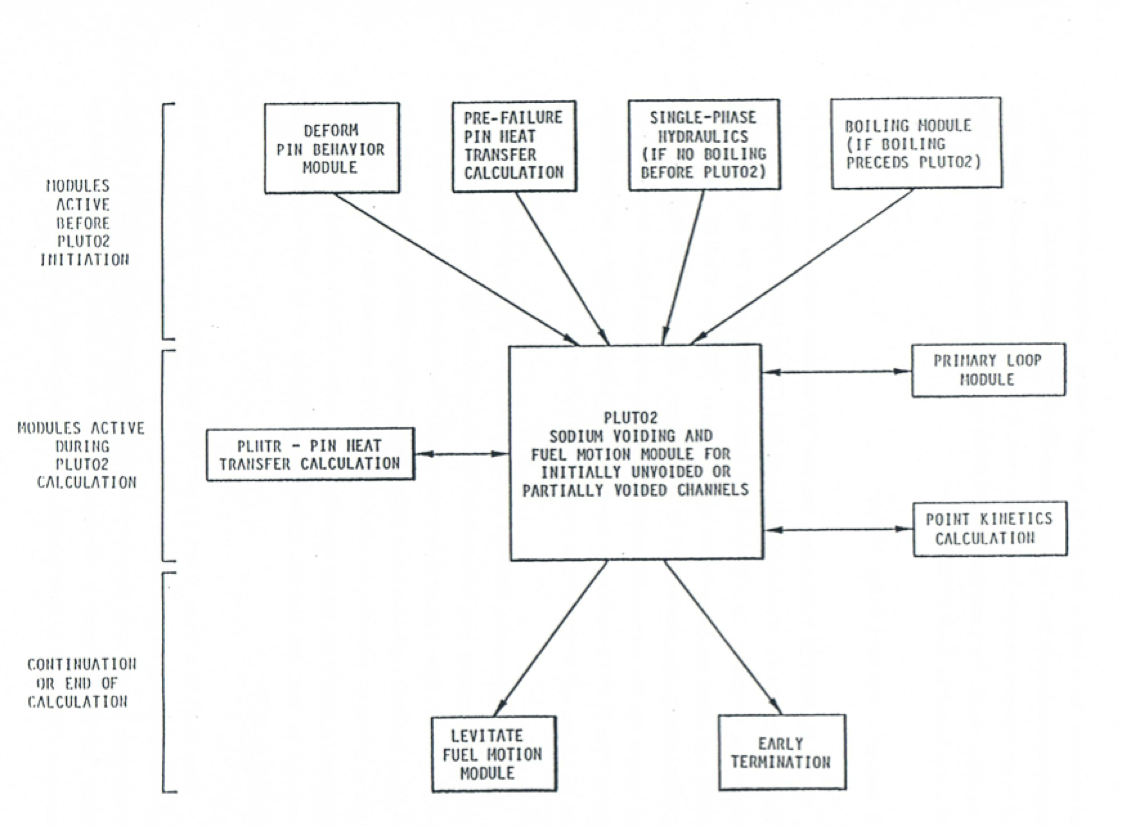

Either PLUTO2 or LEVITATE is initiated once the subroutine FAILUR has predicted pin failure and a minimum fuel melt fraction equal to the input parameter FMELTM exists at the failure node. Subroutine FAILUR is usually called from the driver of the DEFORM pin‑behavior module. However, in the case when cladding motion has already begun, it is directly called from the transient SAS4A driver routine TSTHRM. The decision as to which one of the two modules, PLUTO2 or LEVITATE, is to be initiated depends on the existence and size of a boiling region at the time of pin failure and whether the pins are predicted to fail into a voided or unvoided region of the coolant channel. If there is no boiling, as in an intermediate ramp rate TOP accident or if the pins fail into the liquid region of a partially voided channel, PLUTO2 will be initiated because of its capability of treating FCI’s and sweepout of particulate fuel. For the case of fuel failing into a multibubble boiling region, PLUTO2 will only be initiated if the average void fraction in this region is less than 70%. If the average void fraction is larger or if cladding motion has begun, LEVITATE will be initiated.

The PLUTO2 initialization is described in more detail in Section 14.7.1. The subroutines involved in this procedure are PLINPT, PLSET, PLSETl, and PLSAIN. In these routines all permanent PLUTO2 variables are either set to input values or values calculated by the single‑phase hydraulics, the pin heat‑transfer routines, the pin behavior module DEFORM, or the boiling module. It should also be mentioned here that the flag ICALC, which designates which major module is currently active, will be set to 3 if PLUTO2 has been initialized and to 2 if LEVITATE has been initialized.

Once the PLUTO2 initialization routines have been executed and the flag ICALC has been set to 3, the transient SAS4A driver TSTHRM (see flow diagram in Chapter 2) will call PLUDRV (PLUTO2 DRIVER SUBROUTINE). PLUDRV will retain control and advance the solution using PLUTO2 time steps until the end of the primary‑loop time step is reached. If another SAS4A channel is using PLUTO2 at this time, its solution will also be advanced until the end of the current primary‑loop time step.

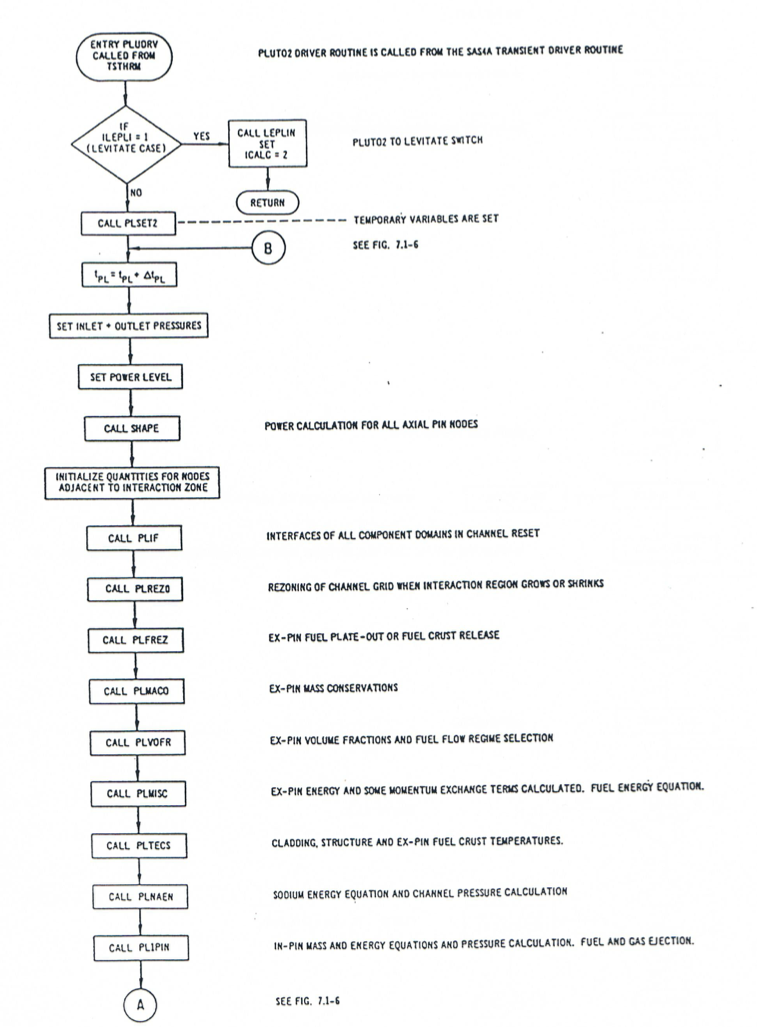

The flowcharts in Figure 14.1.5 and Figure 14.1.6 show the logic of the PLUTO2 driver. They are complete except for an option for switching off all subroutines performing the material velocity calculations. This option is discussed later in this section. If the flag MODEPL, which controls this option, is zero, the flow diagrams in Figure 14.1.5 and Figure 14.1.6 are appropriate.

If the flag ILEPLI has been set to 1 in the PLUTO2 initialization (see Figure 14.7.2 in Section 14.7), LEVITATE will have to be initiated via PLUTO2. In this case, the PLUTO2 driver calls LEPLIN which is the interface routine between PLUTO2 and LEVITATE. The flag ICALC is then set to 2 and control is returned to TSTHRM. The latter will call the LEVITATE driver at the beginning of the next coolant time step upon encountering ICALC = 2 for the channel under consideration (see flow diagram of TSTHRM in Chapter 2).

If ILEPLI is not equal to 1, subroutine PLSET2 will be called (see Figure 14.1.5). In this subroutine, all temporary arrays (i.e., arrays which can be overwritten once control is returned to TSTHRM) are initiated. Moreover, temporary integers are set.

Figure 14.1.5 First Part of the Flow Chart of the PLUTO2 Driver Subroutine, PLUDRV, Showing the Functions of the Major Subroutines¶

Figure 14.1.6 Second Part of the Flow Chart of the PLUTO2 Driver Subroutine, PLUDRV, Showing the Functions of the Major Subroutines¶

Next, the PLUTO2 time is advanced by adding the PLUTO2 time‑step size to the time at the beginning of the PLUTO2 cycle. The time‑step increment for the very first PLUTO2 cycle is an input value which is also the minimum PLUTO2 time‑step size. Later, in the logic flow, the time‑step size is calculated.

Next, the inlet and outlet pressures at the end of the PLUTO2 time step are determined from the PRIMAR calculated inlet and outlet pressures and rates of inlet and outlet pressure changes.

Next, the power level at the end of the PLUTO2 time step is calculated from an exponential fit of the power‑time history that takes the power level at the beginning of the previous and the current main time steps and the precalculated power level at the end of the current main time step into account. By using the calculated power level and the axial input power distribution, the specific power for each axial pin node is calculated. The same specific power is set for the corresponding channel nodes.

In subroutine PSHAPE, which is not a PLUTO2 subroutine, the total power for all axial fuel‑pin nodes is calculated assuming that the pin is still intact. This is needed for the heat‑transfer calculation in the solid fuel annulus in the pin.

Next, cladding and structure temperatures in the nodes adjacent to the interaction region are initialized in order to make sure that they will be available if the interaction zone expands into one of these nodes.

In subroutine PLIF (PLUTO2 INTERFACES), the axial displacements of the sodium slug interfaces, the interfaces of the fission‑gas region and the interfaces of the regions containing fuel are reset. The actual calculations of the velocities needed for this resetting are performed later in subroutine PLMOCO. The initial sodium velocities come from the single‑phase hydraulics or the boiling model and are set in PLSAIN. Fission gas and mobile sodium velocities are always the same in PLUTO2. Subroutine PLIF also calculates the axial pin‑failure propagation and resets the pointer array IDISR(I) which indicates which pin nodes have failed.

In subroutine PLREZO (PLUTO2 REZONE), mesh cells are added to an expanding interaction region or deleted from a shrinking interaction region. Moreover, it cuts off short columns of liquid sodium slugs which are attempting to reenter into a cell of the interaction zone containing frozen fuel or ruptured cladding. The liquid sodium is added homogeneously to such cells. If fuel pins fail into the lower sodium slug, PLREZO will enlarge the interaction region downwards.

In subroutine PLFREZ (PLUTO2 FREEZING ROUTINE), the amount of fuel plating out per time step and per node is calculated. Moreover, PLFREZ calculates the amount of crust released because of remelting or because the underlying cladding has become molten. The released fuel crusts, which have an axial velocity of zero, are mixed with the moving fuel and an updated velocity is calculated by momentum averaging.

In PLMACO (PLUTO2 MASS CONSERVATION), the mass conservation equations for the moving components in the channels are solved. This includes a combined mass conservation for solid or liquid fuel and fuel vapor, and mass conservations for the sodium, free fission gas and dissolved fission gas. There is a special treatment for the top and bottom cells of the channel. Fuel, sodium and fission‑gas will be taken out and stored in a reservoir if the interaction region has extended into the lowermost or uppermost channel cell.

In subroutine PLVOFR (PLUTO2 VOLUME FRACTIONS), the entrainment of the static sodium film by the flow of the two‑phase sodium/fission‑gas mixture and of the fuel particles as well as the de‑entrainment of liquid droplets onto the film, is calculated. PLVOFR also sets the volume fractions of the various components based on the results of the plateout and crust release calculation in PLFREZ and the results of the mass conservation equations. The final section of subroutine PLVOFR is devoted to the selection of the fuel flow regime.

In subroutine PLMISC (PLUTO2 MISCELLANEOUS), several important items are calculated. First, the molten‑ and frozen‑fuel configurations in the flow channel are determined (see Figure 14.4.1). Second, most energy and some momentum exchange terms between the various flow components, cladding and structure are calculated. Because many of these interaction terms depend on the fuel flow regimes, three different exchange coefficients are needed for several of the components. Third, the mobile fuel energy equation is solved.

In subroutine PLTECS (PLUTO2 TEMPERATURE CALCULATION OF CLADDING AND STRUCTURE}, the cladding, reflector, and structure temperatures within the interaction zone are calculated. This calculation is preceded by the determination of the energy exchange coefficients for the frozen fuel crust and the solution of the frozen crust energy equation. Since the energy exchange between fuel crust and moving fuel was not considered in subroutine PLMISC, an updating of the moving fuel energies is also performed here.

In subroutine PLNAEN (PLUTO2 NA ENERGY EQUATION), the two‑phase and single‑phase enthalpy equations for the mixture of sodium and fission gas are solved. From the resulting temperatures and the previously calculated volume fractions (see PLVOFR), the liquid‑phase sodium pressure or the sodium saturation or superheated sodium vapor pressure, as well as the free fission gas pressure, are calculated. In addition, the total end‑of‑time‑step pressure, which includes the fuel vapor pressure, is calculated.

In subroutine PLlPIN (PLUTO2 NO.1 PIN EQUATIONS}, the mass and energy equations for the in‑pin fuel motion are solved. At first, the fuel and free and dissolved fission‑gas mass sources due to fuel melt‑in are calculated and the in‑pin cavity enlargement is determined. Moreover, the free fission‑gas mass sources due to dissolved gas coalescence and the corresponding sinks for the dissolved gas are evaluated. Following these, the fuel mass and energy conservation equations and the free fission‑gas mass conservation equation are solved. Then, a preliminary end‑of‑time‑step pressure is calculated for all cavity cells. This pressure calculation takes the prior‑calculated end‑of-time‑step densities and temperatures into account. Only the pressures in the ejecting nodes will be further updated; in the other cells, the “preliminary end‑of‑time‑step pressure” is the pressure that will actually be used in the momentum equation. The last major item in PLlPIN is the calculation of the mass of fuel and fission gas ejected from all cavity cells that have failed cladding and a pressure higher than that in the corresponding channel cell. The masses of fuel and free and dissolved fission gases in these cavity cells are then reduced and the pressure is updated. The fuel and free and dissolved fission‑gas masses in the channel cells are correspondingly increased and the end‑of‑time‑step pressures in the channel nodes receiving fuel and/or fission gas are updated. The fuel energy in the channel nodes receiving fuel is also updated due to the addition of fuel with a higher temperature.

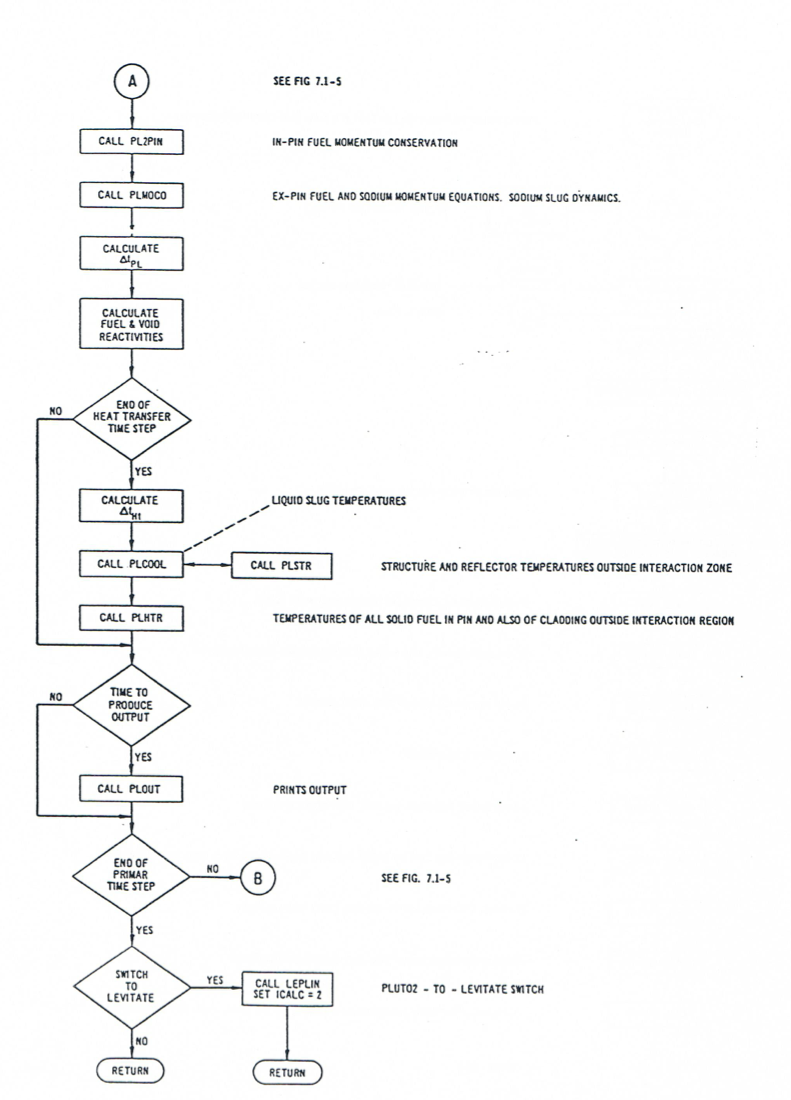

In subroutine PL2PIN (PLUTO2 NO. 2 PIN EQUATIONS), the momentum equation for the homogeneous fuel/fission gas mixture in the molten pin cavity is solved. Next, the mass conservation equation for the dissolved fission gas is solved. This could have been solved earlier in PLlPIN but that routine had become too crowded. The calculation of the time‑step size for the in‑pin calculation during the next time step is also performed in PL2PIN.

In subroutine PLMOCO (PLUTO2 MOMENTUM CONSERVATION), many quantities which were previously needed only at the cell centers have to be defined at the cell edges. Moreover, most of the momentum exchange terms and, in particular, the drag between the fuel and the two‑phase sodium/fission‑gas mixture are evaluated for the particulate and bubbly fuel flow regimes. The main section of this routine deals with the simultaneous solution of the two momentum equations at all cell edges in the interaction region. Moreover, momentum equations will also be solved for fuel particles at either end of the fuel region if the end nodes of the fuel region are in a particulate flow regime. Another section of PLMOCO deals with the calculation of the interaction zone interface velocities. This includes an acoustic approach in the liquid slugs during the first few milliseconds after pin failure and later an incompressible variable‑cross‑section treatment of the upper and lower coolant slugs. Also calculated in PLMOCO are instantaneous coolant slug flow rates for the entire calculational channel, as well as the integrated channel flow rates over a PRIMAR time step. These quantities are needed by the PRIMAR4 module for recalculating the inlet and outlet pressures.

The next task in the PLUTO2 driver routine is the time‑step size determination in the coolant channel. This is compared with the time‑step size calculated for the in‑pin motion and the smaller of the two will be the PLUTO2 time‑step size for the next calculational step.

The next task of PLUDRV is to calculate the transient mass distributions for the fuel and voiding reactivities. This calculation will be described in the next section on the interaction with other SAS4A modules.

If the time at the end of a PLUTO2 time step coincides with the end of the heat‑transfer time step, several heat‑transfer routines are called. This “coincidence” is forced to occur whenever the calculated PLUTO2 time step would overshoot the end of the heat‑transfer time step. In this case, the PLUTO2 time step is set to coincide with the end of the heat‑transfer time step. This is actually done right after the time‑step size calculation described above.

The heat‑transfer time step is determined next. Its maximum value is based on a characteristic heat‑transfer time of the cladding and can be further limited by small primary‑loop time steps which will be small in high power situations because the main (or point kinetics) time step becomes small. Since the heat‑transfer time step is also used for the liquid slug temperature calculations, it can be further limited by a Courant condition based on the slug velocities.

In subroutine PLCOOL (PLUTO2 COOLANT SLUG TEMPERATURE), the temperature in all numerical nodes in the liquid sodium slugs is calculated. This involves the calculation of heat‑transfer exchange terms between liquid sodium and cladding, plenum cladding, reflectors, and structure, and the solution of an energy equation. Moreover, PLCOOL checks whether a node in the lower sodium slug has started to boil.

In subroutine PLSTR (PLUTO2 STRUCTURE TEMPERATURE CALCULATION), the temperatures of the structure, the plenum cladding, and the reflectors outside of the interaction region are calculated.

In subroutine PLHTR (PLUTO2 HEAT TRANSFER), calculations are made of the temperature fields in the solid fuel annulus surrounding the molten fuel cavity, in the unmelted fuel and blanket cells, and in the fuel and blanket cladding outside the interaction region. The heat‑transfer boundary condition at the interface between the molten cavity and the solid fuel annulus is treated by applying a time‑integrated heat flow rate term whose contributions were calculated and summed up in subroutine PLlPIN. The boundary condition between the inner cladding and the outer fuel surface is also based on such an integrated heat flow rate term. The latter is calculated and summed up in subroutine PLTECS, in which the cladding temperature field in the interaction region is calculated using the PLUTO2 time step.

If it is time to produce output, subroutine PLOUT (PLUTO2 OUTPUT) will be called. If the end of the PRIMAR time step has not yet been reached, the logic flow will return to point B (see Figure 14.1.5).

If the end of the PLUTO2 time step coincides with the end of the primary loop time step, a check is made whether the conditions require a switch to the LEVITATE module. This will be necessary if extensive cladding melting has occurred or if complete fuel‑pin disruption is imminent or if the fuel vapor pressures have become quite high. In this case, the LEVITATE‑PLUTO2 interface routine LEPLIN is called and the integer flag ICALC is set to 2 which will assure the calling of the LEVITATE driver routine LEVDRV at the beginning of the next PRIMAR step. Whether a switch to LEVITATE is made or not, control will now be returned to the transient driver TSTHRM.

An option, which is not shown in the flow charts in Figure 14.1.5 and 14.1‑6, allows the user to set all material velocities to small values and to shut off all the subroutines or subroutine sections that are calculating the motion of materials in PLUTO2. This option, which allows an economical but very simplistic continuation of a PLUTO2 calculation for several tens of seconds, is useful for the later treatment of a lead channel failing long before other channels in a low‑ramp‑rate TOP calculation. This situation is most likely to occur when the negative reactivity introduced due to fuel sweepout from the lead channel is not enough to insure permanent subcriticality. This option may be reasonable for subassemblies that are completely blocked by frozen fuel as long as they do not lose much heat to neighboring subassemblies (this subassembly‑to‑subassembly heat loss should eventually be modeled in SAS4A). Moreover, if the fuel in the disrupted assembly heats up too much, it could also become mobile again; this is not currently treated. The above‑mentioned PLUTO2 option will be activated if the input time TIPLMX is exceeded by the PLUTO2 time.

14.1.3. Interaction with other SAS4A Modules¶

During the PLUTO2 initialization, data from several other modules are transferred to PLUTO2 (see Figure 14.1.7). When PLUTO2 is used for a TOP calculation, it requires data from the single‑phase hydraulics, the DEFORM pin behavior module, and the pin heat‑transfer module for non‑boiling conditions (whose driver routine is TSHTRN). When PLUTO2 is used in a SAS4A channel experiencing a LOF’d’TOP condition, data may also be needed from the boiling module and the heat‑transfer module for boiling conditions (whose driver routine is TSHTRV). The PLUTO2 initialization has already been briefly discussed at the beginning of Section 14.1.2 and will be described in more detail in Section 14.7.1.

Once PLUTO2 is active, there will only be an interaction with the point kinetics module and also with the primary loop module if the PRIMAR‑4 module has been selected (see Figure 14.1.7). Moreover, there is an interaction with the PLHTR pin heat‑transfer calculation which is virtually a PLUTO2 routine but uses a different time step than PLUTO2 (see Section 14.1.2). There is no interaction with other modules because PLUTO2 calculates the motion of the liquid sodium slugs (in PLMOCO), has the capability to treat sodium boiling in regions which are not yet occupied by fuel, and also has a simplified calculation of the axial cladding failure propagation (in PLIF).

When PLUTO2 is active, it uses the user input axial fission power distribution with the magnitude calculated by the point kinetics module. PLUTO2 provides the point kinetics module with the sodium and fuel axial mass distributions for all channels in which PLUTO2 is active. Moreover, the Doppler reactivity calculation is based on PLUTO2 calculated average fuel temperatures. The details of these calculations are given in Section 14.6.1.

If the PRIMAR-1 option is chosen PLUTO2 will use a constant outlet coolant plenum pressure which is input and an inlet coolant plenum pressure which is calculated by PRIMAR-1 at the beginning of the transient and later modified by an input table PLUTO2 will not feed back and information to the primary-loop module if the PRIMAR‑1 option has been chosen.

Figure 14.1.7 Data Transfer Between the PLUTO2 Module and the Other SAS4A Module¶

If the PRIMAR‑4 option has been chosen, PLUTO2 uses the time‑dependent inlet and outlet plenum pressures and temperatures which are calculated by PRIMAR‑4. PLUTO2 feeds back to the PRIMAR‑4 module the sodium masses ejected into or received from the inlet and outlet plena during a PRIMAR time step. PLUTO2 also provides the PRIMAR-4 module with the energy of the sodium ejected into the plena and with the liquid sodium flowrates at the end of the PRIMAR time step. This is described in more detail in Section 14.6.2.

The PLUTO2 calculation will be taken over by the LEVITATE module if extensive cladding melting has occurred or if complete pin disruption is imminent or if the fuel vapor pressure becomes quite high. This transition, which can be controlled by input, is necessary because PLUTO2 is not designed to treat these situations. However, the transition to LEVITATE will not occur if only some of the pins have failed in PLUTO2. This PLUTO2 option, which is useful for mild TOP conditions, causes problems for LEVITATE because the latter assumes that all pins have failed when it is initiated.