11.4. Integration into SAS4A/SASSYS‑1 and Usage of Integrated Model

A general purpose SAS-FPIN2 interface has been designed and most of the communication between the two codes is established at this interface minimizing the impacts of coupling on both codes. This coupling strategy allows for maintaining the stand-alone capability of the two codes while assuring that any future improvements to FPIN2 are automatically reflected in SAS4A/SASSYS‑1.

11.4.1. SAS-FPIN2 Coupling Methodology

Two modes of SAS-FPIN2 coupled operations are provided. In the stand-alone mode, FPIN2 reads its own input deck and executes without linking to SAS4A/SASSYS‑1. This mode is provided primarily for verification/debugging purposes, to allow independent development of FPIN2, and to allow it to continue its role as a tool for thermo-mechanical analysis of individual fuel pins.

In the interfaced mode, FPIN2 replaces the SAS4A/SASSYS‑1 metal fuel element mechanics module DEFORM-5 and calculates the updated dimensions, stresses, and strains at the end of each time step. These FPIN2 results are then made available for use in the analysis of accident energetics by providing estimates of axial expansion of fuel, time and location of cladding failure, and the condition of the fuel element at the time of the failure (although the communication between FPIN2 and the SAS4A in-pin and ex-pin fuel relocation modules, PINACLE and LEVITATE, is not yet established). In the interfaced mode, some of the input necessary to run FPIN2 is included in the SAS4A/SASSYS‑1 input deck, and the remaining is interpreted from corresponding SAS4A/SASSYS‑1 variables.

11.4.1.1. Stand-alone FPIN2 Calculation

In the stand-alone mode, FPIN2 is run by a call to main FPIN2 driver routine, FPMAIN. In this mode, FPIN2 performs complete thermal-mechanical calculations for a single fuel element. When the heat transfer option to calculate the coolant and structure temperatures is invoked, the fuel element is assumed to be surrounded by a circular coolant channel and an outer wall in pin-in-a-pipe geometry. The code also provides an option in which the cladding outer surface temperature may be specified as a function of time to drop the coolant channel and structure calculations. This mode is mainly provided for direct verification and code debugging purposes.

In the stand-alone mode, FPIN2 input is appended at the end of SAS4A/SASSYS‑1 input deck after the ENDJOB record. The stand-alone FPIN2 input deck consists of the following records entered in free format:

Title,

Integer data (including integer debug data),

-1/ End of Integers,

Decimal data (including decimal debug data),

-1/ End of Decimals.

Integer and decimal input data are entered in a form similar to the SAS4A/SASSYS‑1 input data. Each of the FPIN2 input variables has an assigned location number. The first entry in a line of input data is the location number of the first member of the set of input data values. The second entry is the number of data values that follow. Integer and decimal input data fields are initialized to zero before reading in the data; therefore, a variable does not have to be read in if it has the value of zero. A line of data may continue over several records; however, the maximum number of data values in a line is limited with 2000. The primary unit system for stand-alone FPIN2 input and output is CGS with exception of pressure which is specified in Bar. Temperature is specified in Kelvin. The full list of FPIN2 input variable for stand-alone calculation along with a brief description for each variable is provided in Section 11.7.2.

11.4.1.2. Interfaced SAS-FPIN2 Calculation

The SAS-FPIN2 interface consists mainly of the steady-state and transient FPIN2 driver routines. The steady-state driver, FPINIT, performs setup of FPIN2 for the interfaced calculation and initializes FPIN2 input from SAS4A/SASSYS‑1 data. This routine is executed only once prior to the transient calculations. The transient FPIN2 driver routine, FPDRIV, incorporates the time-advancement scheme and interfaces dynamic variables between the two codes.

During the initialization of FPIN2 from SAS4A/SASSYS‑1 input, interface routine FPINIT looks for inconsistencies in fuel element modeling, prints diagnostic messages, and terminates the execution if necessary. The main inconsistencies that a user should be aware of are summarized below:

A gas plenum below the fuel column is not allowed in FPIN2; therefore, the execution is terminated if SAS4A/SASSYS‑1 input variable

IPLUPis non-zero.If the fuel element contains axial blankets, i.e.,

MZUBand/orMZLBare non-zero, a warning message is printed since FPIN2 mechanics calculation is not normally performed for the axial segments containing blanket fuel. [1]An error message is printed and execution is terminated if the number of axial segments in fuel exceeds FPIN2’s limit (20),

An error message is printed if SAS4A/SASSYS‑1 input variable

IPOWRZis non-zero (applicable only whenIHTFLG≠0).Cross-checking of the input data for abnormalities are also performed (such as zero pin pressure) and diagnostic messages are printed.

Since FPIN2 has been primarily developed for the transient analysis of fuel elements, it lacks models to describe pre-transient irradiation features such as fuel restructuring, fission gas retention and fuel-cladding gap narrowing. These pre-transient conditions are to be provided as input for the metallic fuels as discussed in Section 11.4.3. The as-irradiated geometry, fuel elongation, fission product and porosity distributions, and the effect of fast neutron fluence on cladding are typically obtained from the relevant in-reactor fuel performance database at a desired burnup, or from steady-state fuel performance codes such as LIFE-METAL [11-18] and STARS [11-6]. FPIN2 has the capability to interpret its input from the LIFE-METAL output. This capability is also extended to the integrated SAS-FPIN2 model.

Normally, FPIN2 heat transfer is by-passed in the interfaced mode and the fuel element temperatures are lined with SAS4A/SASSYS‑1 calculated fuel, cladding, plenum, and cavity temperatures. To accomplish this by-pass, the FPIN2 mechanics/thermal-hydraulics boundary is identified, and routines that are used in heat transfer calculation are isolated. All the common block variables that are used in the mechanics calculation (but altered in one of these heat-transfer routines) are linked with their SAS4A/SASSYS‑1 counterparts. The FPIN2 results for stresses and displacements are in turn made available to SAS4A/SASSYS‑1 for the estimates of axial expansion of fuel and associated reactivity effects, time and location of cladding failure, and the condition of the fuel at the time of failure.

In the interfaced mode, setting the input flag, IHTFLG, may also turn on FPIN2’s own heat transfer model. The option for including FPIN2 heat transfer model is mainly provided for debugging and code verification purposes. It requires additional data to be interfaced regarding fuel pin heat generation rate and cladding outer surface temperature for each axial segment at each time step as the dynamic boundary condition. When this option is set, FPIN2 uses its own built-in metallic fuel thermal property routines.

In order to establish consistency between SAS4A/SASSYS‑1 and FPIN2 calculations in the interfaced mode, some modifications to the FPIN2 code were necessary. Major changes to FPIN2 for this integration are summarized below:

Generic precision conversions are performed by combining all type declaration statements in a file and replacing them in each subprogram with an INCLUDE statement referencing this file.

Along the same line, type specific intrinsic functions are converted to their generic equivalents.

Various table interpolations for time-dependent boundary conditions (pin power and cladding outer surface temperature when IHTFLG=1) are bypassed and these variables are linked with their SAS4A/SASSYS‑1 calculated counterparts.

Various calls to built-in FPIN2 material thermal property subprograms are also bypassed and the thermal properties that are needed in FPIN2 mechanics calculation are substituted with their SAS4A/SASSYS‑1 calculated equivalents.

Steady-state and transient pin plenum gas temperature is interfaced with the corresponding SAS4A/SASSYS‑1 variable.

Constant liquid eutectic alloy melting temperature is converted to a variable and listed as an integrated SAS-FPIN2 model input, XEUTHR.

Initial cladding effective inner surface wastage is described as a new integrated SAS-FPIN2 model input variable and incorporated into FPIN2 by defining it as part of the variable for cladding wall thinning due to eutectic penetration.

The constant coolant channel pressure is converted to a dynamic array variable and interfaced with its axially varying time-dependent SAS4A/SASSYS‑1 counterpart.

All these changes are implemented in such a way that they do not affect the stand-alone performance of FPIN2.

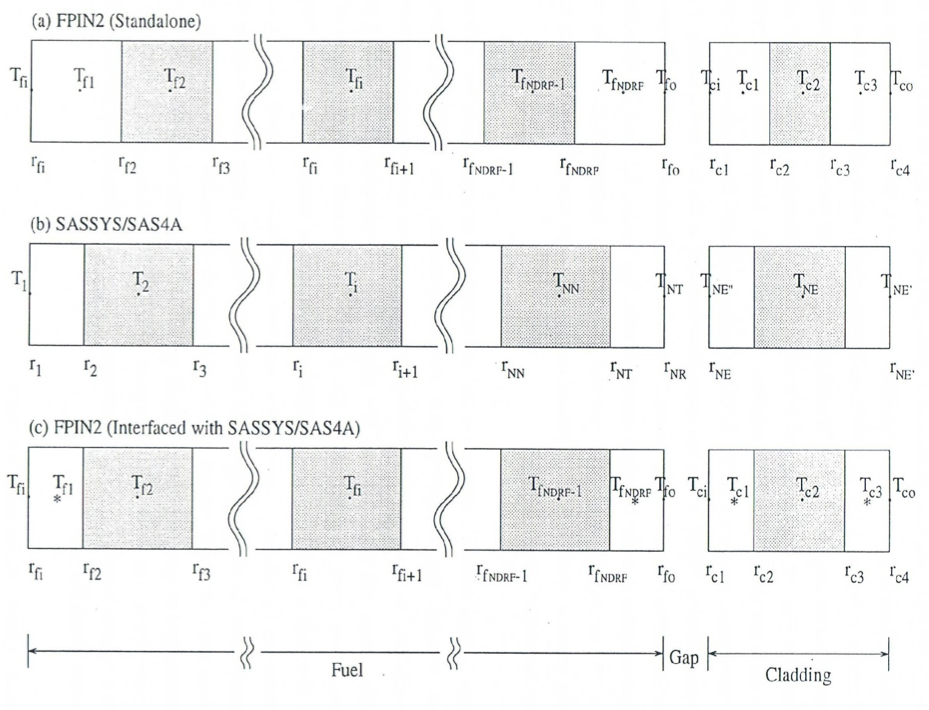

The radial mesh structure for SAS4A/SASSYS‑1, stand-alone FPIN2, and interface SAS-FPIN2 calculations are shown in Figure 11.4.1. As presented in Chapter 3, the radial mesh structure in SAS4A/SASSYS‑1 for fuel elements at a given axial segment can be set up based on either equal radial difference or equal mass principle. In either case, the boundary nodes are the half sixe as shown in Figure 11.4.1. In FPIN2, on the other hand, finite elements are initially defined in a mesh based on an equal radial difference principle with all elements having the same thickness as shown in Figure 11.4.1. In order to avoid extensive remapping of the thermal and mechanical variables between two meshes during the interfaced calculations, the consistency between the initial mesh structures is accomplished by pulling SAS4A/SASSYS‑1-calculated mesh information into FPIN2 common blocks, and forcing FPIN2 to use the same mesh structure in the fuel and cladding (Figure 11.4.1). When FPIN2 heat transfer is by-passed, however, this procedure requires substitution of mesh-centered temperatures for boundary nodes, namely Tf1, TfNDRF, Tc1, and Tc3 (locations marked with a “*” in Figure 11.4.1), that are not calculated in SAS4A/SASSYS‑1. In the interfaced mode, these temperatures are approximated with a linear interpolation between the temperatures of the neighboring nodes.

Figure 11.4.1 Radial Mesh Structure and Temperature for an Axial Segment in (a) FPIN2 Code, (b) SAS4A/SASSYS‑1, and (c) Integrated SAS-FPIN2 Model.

Although the fuel element mechanics model of FPIN2 uses an implicit solution scheme, the interaction between the SAS4A/SASSYS‑1 thermal-hydraulics and FPIN2 mechanics calculations is explicit. In the SAS4A/SASSYS‑1 code system, a multi-level time-step hierarchy is used in which a main time step is divided into one or more primary-loop, heat transfer, and coolant dynamics time steps as described in Chapter 2. The control over the length of a computational time step is performed using a variety of internal and user-specified restrictions. The FPIN2 mechanics calculation is performed at the each heat transfer time step using newly calculated temperatures. Limitations imposed by stability and accuracy requirements assure that heat-transfer time steps are small enough to avoid the problem of unstable results between the thermal and mechanical calculations due to explicit coupling. The implicit treatment in FPIN2 is somewhat inconsistent with the explicit nature of the SAS4A/SASSYS‑1 code system and it often results in a notable increase in computation time. However, the capabilities gained by this coupling are often well worth this additional computational cost.

11.4.1.3. Subroutine Descriptions and Flow-charts

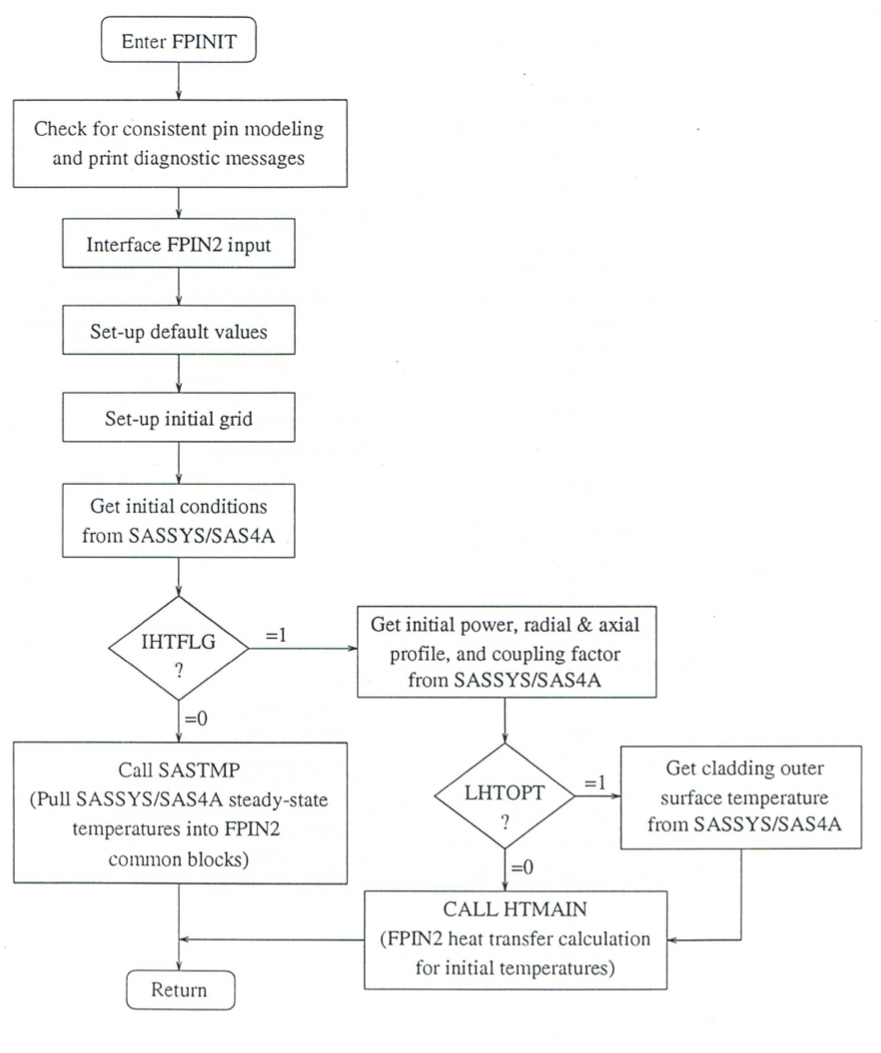

The list of SAS-FPIN2 interface routines is presented in Table 11.4.1. In the stand-alone mode, the FPIN2 main program is called form the SAS4A/SASSYS‑1 steady-state driver routine SSTHRM and FPIN2 is executed without interfacing to SAS4A/SASSYS‑1. In the interfaced mode, FPIN2 is coupled to the rest of the SAS4A/SASSYS‑1 calculations through two main driver subroutines, FPINIT and FPDRIV. First the steady-state FPIN2 driver routine FPINIT is called from SSTHRM for initialization of FPIN2 for interfaced calculations. A flowchart for the FPINIT subroutine is shown in Figure 11.4.2. Then, during the transient calculations, SAS4A/SASSYS‑1 thermal-hydraulic manager TSTHRM calls for the transient interface routine FPDRIV that acts as the FPIN2 transient driver.

Subroutine Name |

Description |

|---|---|

FPMAIN |

In the stand-alone mode, FPIN2 driver (main program) |

FPINIT |

In the interfaced mode, steady-state FPIN2 initialization routine |

FPDRIV |

In the interfaced mode, FPIN2 transient driver routine |

SASTMP |

In the interfaced mode, SAS-FPIN2 thermal-hydraulics interface (when FPIN2 heat transfer module is by-passed) |

FPNOUT |

In the interfaced mode, output of the FPIN2 results |

Figure 11.4.2 FPINIT Subroutine Flow Diagram

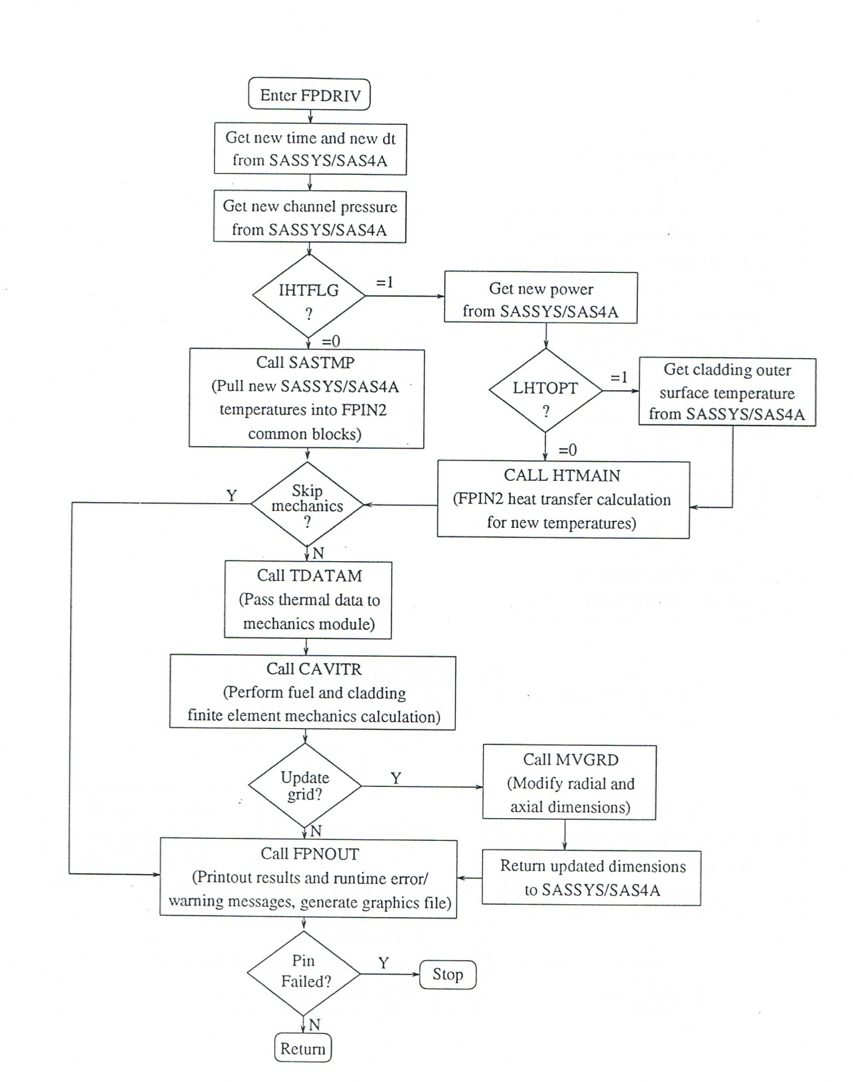

Subroutine FPDRIV basically includes the section of FPMAIN that is used for the time advancement scheme. This time advancement scheme is preceded by an upper interface routine, SASTMP that pulls SAS4A/SASSYS‑1 calculated temperatures into FPIN2 common blocks, and is followed by a lower interface section that takes FPIN2 updated axial and radial mesh information and puts it back into SAS4A/SASSYS‑1 common locations. SASTMP is also used by steady-state interface routine FPINIT to extract the initial temperature distribution from SAS4A/SASSYS‑1. A flowchart for the subroutine FPDRIV is presented in Figure 11.4.3.

11.4.2. Input Description for Interfaced SAS-FPIN2 Calculation

Two groups of input variables are identified for interfaced SAS-FPIN2 calculations. Integrated model variables that describe the mode of the interfaced calculation and FPIN2 variables that are not readily provided by SAS4A/SASSYS‑1 are included in SAS4A/SASSYS‑1 common blocks INPCHN (for integer variables) and PMATCH (for real variables). The list of these “new” variables is provided in Table 11.4.2.

Another category includes input variables that are provided by SAS4A/SASSYS‑1 calculations and/or are translated from SAS4A/SASSYS‑1 input. The list of these variables along with SAS4A/SASSYS‑1 counterparts is presented in Table 11.4.3. The variables in Table 11.4.2 and Table 11.4.3 constitute the full list of input parameters necessary to run FPIN2 in the interfaced mode. Further information on some of the input parameters related to pre-transient fuel element characterization is given in the following section. When interpreting FPIN2 input from SAS4A/SASSYS‑1 data, dimensional conversions are necessary since the principal unit systems for SAS4A/SASSYS‑1 and FPIN2 and SI and CGS, respectively.

Figure 11.4.3 FPDRIV Subroutine Flow Diagram

BLOCK 51 * INPCHN |

|||

|---|---|---|---|

Location |

Symbol |

Value |

Definition/Comments |

285 |

IFPIN2 |

=0 |

Do not use FPIN2 metal fuel model |

=1 |

Use FPIN2 |

||

(Note: No other data required when IFPIN2=0) |

|||

286 |

IFPI01 |

=0 |

Use FPIN2 in interfaced mode |

=1 |

Use FPIN2 in standalone mode |

||

(Note: No other data required when IFPI01=1) |

|||

287 |

IHTFLG |

=0 |

Bypass FPIN2 heat transfer calculation |

=1 |

Include FPIN2 heat transfer calculation |

||

288 |

LHTOPT |

=0 |

Perform heat transfer calculation including coolant and wall |

=1 |

Perform heat transfer calculation with input value of cladding outer surface temperatures |

||

289 |

LCRACK |

=0 |

No fuel cracking |

=1 |

Radial fuel cracks included |

||

290 |

LFPLAS |

=0 |

Allow creep-plastic strains in fuel |

=1 |

Suppress creep-plastic strains in fuel |

||

291 |

LCPLAS |

=0 |

Allow creep-plastic strains in clad |

=1 |

Suppress creep-plastic strains in clad |

||

292 |

LFSWEL |

=0 |

Allow swelling-hotpressing strains in fuel |

=1 |

Suppress swelling-hotpressing strains in fuel |

||

293 |

LCSWEL |

=0 |

Allow swelling strains in clad |

=1 |

Suppress swelling strains in clad |

||

294 |

LLRGST |

=0 |

Large strain analysis |

=1 |

Small perturbation analysis |

||

295 |

LFCSLP |

=0 |

Fuel-clad locked when gap is closed |

=1 |

Independent fuel-clad axial displacement |

||

296 |

LOUTSW |

=0 |

No detailed printing of results - summary only |

=1 |

Normal detailed printout under LFREQA, MFREQA, and LFREQB control |

||

297 |

LFREQA |

Initial print frequency, number of time steps between normal detailed printout |

|

298 |

MFREQA |

Total number of time steps under LFREQA control |

|

299 |

LFREQB |

Final print frequency |

|

300 |

LGRAPH |

=0 |

Do not write graphics file |

=1 |

Write a graphics data file |

||

301 |

LDBOUT |

=0 |

Do debug output |

=1 |

Add debug output to regular LOUTSW=2 output |

||

302 |

LDBSTP |

=0 |

Program stops when molten cavity freezes |

=1 |

Ignore this program stop |

||

303 |

LDBFPL |

=0 |

Use recommended fuel flow stress Eq. (11.3-16) |

=1 |

Use simple power law fuel creep:˙ε=C0σC1e (Note: XFPLC0 and XFPLC1 are required) |

||

304 |

LDBFDV |

=0 |

Use recommended fuel swelling-hotpressing Eq. (11.3-30) |

=1 |

Use equilibrium swelling model (ANL-IFR-6 and -23) |

||

=2 |

Use simple power law fuel swelling: ˙ε=C0σC1m (Note: XFDVC0 and XFDVC1 are required) |

||

305 |

LDBCPL |

=0 |

Use recommended clad flow stress |

=1 |

Ideal plastic flow for clad: σy=C0+C1¯εp (Note: XCIPL0 and XCIPL1 are required) |

||

=2 |

Use high-temperature power-law creep |

||

=3 |

Use simple power law clad creep: ˙ε=C0σC1e (Note: XCIPL0 and XCIPL1 are required) |

||

306 |

LGPRES |

(Not currently used) |

|

307 |

LGAPCL |

=0 |

Use fuel-clad opening/closure model |

=1 |

Fuel-clad gap always closed |

||

308 |

LCPROP |

=0 |

Use material property correlations (when IHTFLG=1) |

=1 |

Use temperature independent material properties (when IHTFLG=1) |

||

309 |

LSKIPM |

=0 |

Perform mechanical calculations |

=1 |

Bypass mechanical calculations, heat transfer only (when IHTFLG=1) |

||

310 |

LGCLOS |

=0 |

Use gap closure routine at 100% fuel melting |

=1 |

Do not close gap (if open) at 100% fuel melting |

||

311-334 |

LDBOTA(J) |

Axial debug print vector (0=no-print, 1=print) |

|

355-345 |

LDBOTF(I) |

Fuel radial debug print vector (0=no-print, 1=print) |

|

346-348 |

LDBOTC (IC) |

Clad radial debug print vector (0=no-print, 1=print) |

BLOCK 63 * PMATCH |

||

|---|---|---|

Location |

Symbol |

Definition/Comments |

105 |

XEUTHR |

Liquid eutectic threshold temperature (K) (Default=988.) (See |

106 |

XGBFRA |

(Not currently used) |

107-130 |

XCLDHR(J) |

Pre-transient hardness parameter used in clad flow stress calculation. (Default value is 0.223, the value appropriate for 20% CW unirradiated stainless steel.) |

131 |

XFPLC0 |

Fuel power law creep constant C0 (when LDBFPL=1) |

132 |

XFDVC1 |

Fuel power law creep constant C1 (when LDBFPL=1) |

133 |

XFDVC0 |

Fuel power law swelling constant C0 (when LDBFDV=2) |

134 |

XFDVC1 |

Fuel power law swelling constant C1 (when LDBFDV=2) |

135 |

XCIPL0 |

Clad idealized flow stress constant C0 (when LDBCPL=1 or 3) |

136 |

XCIPL1 |

Clad idealized flow stress constant C0 (when LDBCPL=1 or 3) |

137 |

XHTERR |

Relative convergence criterion for heat transfer calculation (when IHTFLG=1) (Default=0.0005) |

138 |

XEPSCA |

Relative convergence criterion for cavity pressure (Default=0.001) |

139 |

XEPSFE |

Relative convergence criterion for finite element analysis (Default=0.0005) |

140 |

XEPTES |

Relative convergence criterion for plastic-creep strains (Default=0.0005) |

141 |

XEVTES |

Relative convergence criterion for swelling strains (Default=0.0005) |

Description |

FPIN2 Variable |

SAS4A/SASSYS‑1 Counterpart |

|---|---|---|

Metal fuel type (U-Fs, binary, or ternary) |

IFTYPE |

IMETAL |

Cladding type (Type 316, D9, or HT9) |

ICTYPE |

ICTYPE |

Number of axial segments in fuel column |

NDZ |

MZ |

Number of radial elements in fuel |

NDRF |

NT |

Number of radial elements in cladding |

NDRC |

3 |

Transient initiation time (s) |

TZERO |

|

Computation time step size (s) |

DTIME |

DTP |

Initial height of axial segments |

DZ(J) |

AXHI(J) |

Initial length of plenum (cm) |

ZPLENM |

PLENL |

Initial length of bond sodium in plenum (cm) |

ZPLNA |

BONDNA, pin geometry |

Gas constant for plenum gases (Bar-cm3/gm-K) |

PLGASR |

RGASSI, HEMM, FGMM, P0GAS, FGFI |

Gas constant for central cavity gases (Bar-cm3/gm-K) |

GASCON |

RGASSI, HEMM, FGMM |

Initial pin pressure (Bar) |

PINT |

P0GAS |

Reference temperature at which PINT is specified (K) |

PLTREF |

TR |

External (channel) pressure (Bar) |

PEXT |

PCOOL2(J) |

Plenum gas temperature (K) |

PGASTM |

TGASP2 |

Description |

FPIN2 Variable |

SAS4A/SASSYS‑1 Counterpart |

Peak fuel burnup (at.%) |

BURNUP |

BURNFU |

Fuel radial mesh array (cm) |

RADF(I,J) |

R(I,J) |

Clad radial mesh array (cm) |

RADC(I,J) |

R(NE,J), R(NEP,J) |

Distribution of fission gas in closed porosity or in solution (gm/cm3) |

FISGAS(I,J) |

ROGSPI, BURNFU, FIFNGB |

Fraction of FISGAS on grain boundaries (Default=0.10) |

GBFRAC |

FIFNGB |

Distribution of total fuel porosity |

PORES(I,J) |

PRSTY2(I,J) (based on PRSTY(IFUELV)) |

Axial profile of cladding fluence (1022 n/cm2) |

CLDFLU(J) |

BURNFU, FPDAYS, PBAR(J), FLTPOW, AXHI(J) |

Effective cladding inner surface wastage thickness (cm) |

WASTE |

TWASTI, TWASTO |

Mass of fuel elements (gm) |

FMASS(I,J) |

FUELMS(I,J) |

Mass of cladding elements (gm) |

CMASS(I,J) |

DENSS, cladding geometry. |

Distribution of Pu in ternary fuel |

FRACPU(I,J) |

FUPUMS(I,J), FUELMS(I,J) (based on PUZRTP(IFUELV)) |

Distribution of Zr in ternary fuel |

FRACZR(I,J) |

FUZRMS(I,J), FUELMS(I,J) (based on PUZRTP(IFUELV)) |

Fuel solidus temperature (node-by-node) (K) |

FTSOL(I,J) |

TSOLIJ(I,J) |

Fuel liquidus temperature (node-by-node) (K) |

FTLIQ(I,J) |

TLIQIJ(I,J) |

Normalized time dependent reactor power (when IHTFLG=1) |

POWNEW |

QMULT |

Pin power coupling factor (when IHTFLG=1) |

QCONST |

|

Axial profile of energy generation rate (normalized) (when IHTFLG=1) |

QAX(J) |

PSHAPE(J) |

Radial profile of energy generation rate (W/gm) (when IHTFLG=1) |

QR(I,J) |

RADPRS(I,J), POW, GAMTNE, GAMTNC, GAMSS, FUELMS |

Cladding outer surface temperature (K) (when IHTFLG=1 and IHTOPT=1) |

TCSURF(J) |

T2(NEP,J) |

11.4.3. Pre-transient Fuel Element Characterization

The steady-state fuel element characterization forms the initial conditions from which the transient calculations begin. The FPIN2 mechanics calculation is initiated from a stress-free state for hot and irradiated (swollen) fuel elements. Prior irradiation of fast reactor fuel elements influences their thermal and mechanical response during accident transients significantly. The pre-transient features that are more important for metallic fuels are fuel geometry, fission product, alloy, and porosity distributions, fuel elongation, and the effects of fast neutron fluence on transient cladding properties. These initial conditions can be obtained from the in-reactor fuel performance database or from a fuel performance computer code. In this section, the methods that are suggested to determine the fuel element pre-transient characterization are outlined.

11.4.3.1. Zone Formation

Post-irradiation destructive examinations of ternary fuel pins irradiated in EBR-II reveal significant migration of plutonium and zirconium. This redistribution produces distinct zones that are associated with different metallurgical phases. Micrographs from irradiated ternary fuel pins typically show a three-ring structure that could be separated physically for examination [11-19]. Analysis of these rings reveals that the intermediate zone is depleted in zirconium while the inner and outer zones are enriched in zirconium. The weight fraction of plutonium, on the other hand, remains nearly uniform. The Zr deficient central zone generally consist of the high temperature γ phase in which all constituents are mutually soluble in the solid sate as described in Section 11.3.4. The primary influence of alloy redistribution and zone formation on transient fuel response is through the changes in fuel material properties with alloy content. The most dramatic change is in the fuel solidus temperature where zirconium depletion may lead to initial fuel melting at a radial location other than the hotter axial centerline.

SAS4A/SASSYS‑1 provides capabilities to model this fuel composition

variation by zone in metallic fuels (IMETAL=2)

as discussed in Section 10.3.5. This multiple radial fuel zone option is

invoked by setting IFUELC=1. The distributions

are determined by fixing the zone boundaries and the alloy content of

the each zone (see input variables IZNC,

IZNM, and MFTZN). The representative alloy distributions that are chosen to

characterize ternary fuel to be analyzed are specified in the input as

weight fractions for each fuel type (PUZRTP). These distributions are used in the fuel material property

routines to determine variations in properties with alloy content.

SAS4A/SASSYS‑1 converts this zone information to internal arrays that describe metal fuel composition and composition-dependent quantities on a node-by-node basis. In the integrated SAS-FPIN2 model, FPIN2 interfaces with these internal SAS4A/SASSYS‑1 arrays to initialize variable FRACPU(I,J), FRACZR(I,J), FTSOL(I,J), FTLIQ(I,J) and FMASS(I,J).

11.4.3.2. Fission Gas Distribution

Fission gas plays an important role in transient fuel element response. The gas that is retained in the fuel during steady-state irradiation provides a source for expansion of both solid and liquid fuel during overheating. The quantity of fission gas in the plenum is also important since the plenum pressure is a major contributor to cladding loading. The distribution of fission gas retained in the fuel matrix is specified as input in FPIN2 (FISGAS(I,J)). Part of this gas is assigned to grain boundary bubbles (GBFRAC) and the remainder of the gas is assumed to be in solution or in small bubbles within the fuel grains. A number of models that address the various aspects of fission gas behavior are available. One of these, the STARS code gives a detailed self-consistent picture of the distribution of the gas between the fuel matrix, grain boundaries, edge tunnels, large pores, and the plenum [11-6].

The fraction of the retained gas on the grain boundaries increases with burnup as more gas is released and as the plenum pressure becomes significant compared to surface tension constraint on the grain boundary bubbles. In the integrated model, the distribution of fission gas in fuel closed porosity and in solution is calculated from SAS4A/SASSYS‑1 input variables according to following formula

where the fraction of fission gas on grain boundaries is simply

The unit of FISGAS(I,J) in Eq. (11.4-1) is gm/cm3. The default value of GBFRAC is 0.10.

The two other relevant input information required by FPIN2 are the plenum and cavity gas constants, PLGASR and GASCON, in Bar-cm3/gm-K. For fresh fuel pins (BURNFU=0) these constants are simply calculated from

For irradiated pins (BURNFU≠0) the following formulas are used

11.4.3.3. Porosity Distribution

The porosity distribution is also input into FPIN2 (through PORES(I,J) variable). As given in the input description in Table 11.4.3, these values are the total porosity of the nodes, exclusive of the volume of any macroscopic cracks (crack volumes are specified separately as input). The difference between the total porosity and the grain boundary bubble porosity is equal to the porosity of the large pores that are free of surface tension restraint. These large pores may be interconnected (open) or closed. In FPIN2, however, all large pores are assumed to be open and fission gas residing in the open porosity after steady-state irradiation is calculated from the local open pore volume and temperature assuming that the pore pressure is in equilibrium with the plenum pressure. This gas is assumed to be trapped in the fuel during transient heating.

Few measurements of porosity distributions are available for the

metallic fuels. Therefore, the fractional porosity is generally

determined from the fuel geometry, the fuel mass, and the fuel and

fission product densities assuming a uniform distribution. In

SAS4A/SASSYS‑1, porosity distribution is specified on a zone-by-zone basis

using the porosity values for eight fuel types (PRSTY) as described in Section 11.4.3.1. Integrated model

interfaces with an internal SAS4A/SASSYS‑1 array variable (PRSTY2(I,J) to

get final distribution on a node-by-node basis.

The magnitude and distribution of the total porosity do not play a large role in mechanics calculation as long as there is sufficient volume to accommodate the grain boundary bubbles so that the resultant open porosity is greater than zero. The FPIN2 models assume that the open porosity does not contribute to solid fuel swelling or to hot pressing because.

Sodium logging may partially fill the pores,

Driving pressures for swelling are small since the voids are connected to the plenum,

Most of the voids are probably large enough so that the time constants for their growth are long compared to the span of the accident transient [11-14].

The distribution of open porosity does not significantly influence the mechanics results either. Although fission gas in the open pores is trapped at the time of fuel melting, its pressure is in equilibrium with the plenum pressure so that this gas contributes little to molten fuel expansion. Most of the expansion comes from the grain boundary gas or the gas in solution in the fuel matrix that has significant swelling potential when it collects into large bubbles following fuel melting. Coalescence of small bubbles into large bubbles is very rapid in liquid fuel [11-20] and is assumed to occur instantaneously in the FPIN2 calcualtion of molten fuel extrusion.

11.4.3.4. Cladding Fluence

The axial distribution of the cladding fluence is needed in life fraction correlation evaluations. In the integrated SAS-FPIN2 model, this variable is determined from the following formula

Were FPDAYS, FLTPOW, and AXHI(J) are SAS4A/SASSYS‑1 input variables, and

PBAR(J) is an internal SAS4A/SASSYS‑1 array variable. The unit of

CLDFLU(J) in this equation is 1022 neutrons/cm2. For

applications where fast-flux to linear-power ratio (FLTPOW)

is not available, cladding fluence is approximately set

equal to the burnup in at.% (i.e., BURNFU). [2]

11.4.3.5. Length of Sodium in Plenum

The initial length of sodium in the pin plenum is expected to be

specified for hot and irradiated conditions in FPIN2. In the integrated

model, this value is calculated internally using SAS4A/SASSYS‑1 subroutine

NABOND. This subroutine evaluates the gap thickness for each axial

segment and determines the amount sodium in the plenum from initial mass

of sodium added to produce the fuel-cladding bound (BONDNA). The length in sodium in the plenum then is calculated from

plenum geometry consistent with the steady-state temperature

distribution.

11.4.3.6. Effective Cladding Inner Surface Wastage

The integrated SAS-FPIN2 model provides an extended capability to

include the effects of cladding wastage on fuel element mechanics that

is not an original part of the FPIN2 code. The SAS-FPIN2 interface has

been modified to include two SAS4A/SASSYS‑1 input variables describing

initial wastage thicknesses on the cladding inner and outer surfaces

(TWASTI and TWASTO, respectively.)

Cladding wastage is typically considered in design-basis safety assessments. The bases of the wastage in metallic fuel elements are the scratches on the cladding surfaces, diffusion of fuel constituents and fission products into the cladding, and the eutectic formation at the fuel cladding interface. Diffusion of fuel and fission products creates a lanthanide rich FCCI zone that has distinctly different microstructure with cracks and it is assumed to be strengthless. In addition, a separate carbon depleted band with decreased hardness is often identified next to the FCCI zone in HT9 cladding. Although this region exhibits only a moderate decrease in strength, it can conservatively be considered as part of the wastage for the safety cases.

In the integrated SAS-FPIN2 model, effective inner surface wastage is defined as the sum of inner and outer surface wastages and it is incorporated into the mechanics calculation by defining them as part of an FPIN2 variable describing the cladding eutectic penetration. This allows consideration of the wastage bands as part of the cladding for heat transfer while the stress field is determined considering only the thickness of unaffected cladding that is available to carry the load.

11.4.4. Output Description and Graphics File Usage

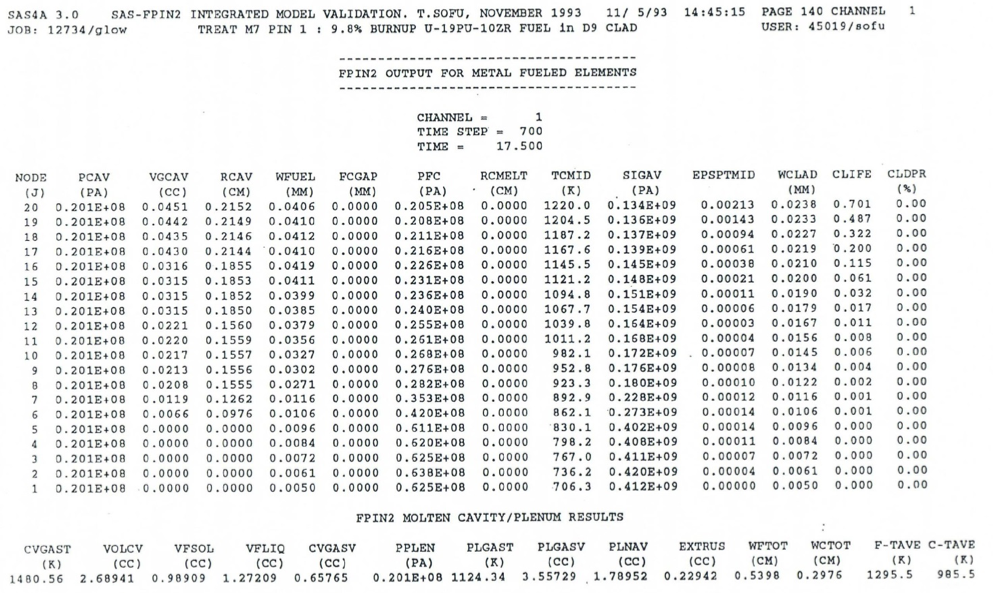

A brief description of the output generated by FPIN2 in the interfaced mode is as follows. A sample of the regular output for fuel/cladding summary information and plenum/molten cavity results is shown in Figure 11.4.4. In the first part of the output, FPIN2 mechanics results are printed for each axial segment separately. The descriptions of the variables printed in this category are presented in Table 11.4.4. FPIN2 regular output for each axial segment is followed by a summary of plenum/molten cavity results as shown in the bottom portion of Figure 11.4.4. The description of the variables printed in this category is presented in Table 11.4.5.

In addition to regular FPIN2 output described above, a series of diagnostic messages are also printed as part of SAS4A/SASSYS‑1 output as the integrated model calculations progress. These diagnostic messages can be categorized as follows:

Messages regarding the execution of the FPIN2 such as non-convergent iterations and maximum iteration warnings in various parts of the program, and occurrence of non-positive definite matrix,

Messages regarding the non-physical phenomena such as negative gas pressure, inconsistent input for constitutive equation options, or negative open porosity,

Information messages regarding the cladding failure in a particular axial segment, fuel-cladding gap mixup, complete cladding melting, and cavity solidification stop.

A summary of these messages is also printed at the end of the transient calculations.

The FPIN2 detailed output option can be invoked by setting the input

flag LOUTSW=1. This option generates a huge

printout for the details of FPIN2 calculations and it is used for

debugging purposes only. The information printed under this option is

generally self-explanatory; therefore, it is not discussed separately

here. The print frequency of the regular and detailed FPIN2 output

discussed above is controlled by the same SAS4A/SASSYS‑1 input parameters

that control DEFORM5 output.

For graphics use, some of the variables printed in regular output are

stored in binary form in a graphics file at every time step by invoking

the option LGRAPH=1. The logical unit number

assigned for FPIN2 graphics file is 23. The list of variables printed in

the graphics file is presented in Table 11.4.6.

Figure 11.4.4 FPIN2 Regular Output for Fuel Element Mechanics Summary

Variable |

Unit |

Description |

|---|---|---|

PCAV |

Pa |

Molten fuel cavity pressure |

VGCAV |

cm3 |

Volume of gas in molten fuel cavity |

RCAV |

cm |

Outer radius of the molten fuel cavity |

WFUEL |

mm |

Axial displacement of fuel column segment |

FCGAP |

mm |

Fuel-cladding gap thickness |

PFC |

Pa |

Contact pressure between the fuel and cladding (plenum pressure if gap is open) |

RCMELT |

cm |

Radius of cladding melting |

TCMID |

K |

Temperature of cladding at radial midpoint |

SIGAV |

Pa |

Average hoop stress in cladding |

EPSPTMID |

Plastic hoop strain in cladding at radial midpoint |

|

WCLAD |

mm |

Axial displacement of cladding segment |

CLIFE |

Cladding life fraction |

|

CLDPR |

% |

Eutectic penetration of the cladding |

Variable |

Unit |

Description |

|---|---|---|

CVGAST |

K |

Molten fuel average temperature |

VOLCV |

cm3 |

Total molten cavity volume |

VFSOL |

cm3 |

Volume of fuel in molten cavity between solidus and liquidus |

VFLIQ |

cm3 |

Volume of fuel in molten cavity above liquidus |

CVGASV |

cm3 |

Volume of fuel vapor in molten cavity |

PPLEN |

Pa |

Pin plenum pressure |

PLGAST |

K |

Pin plenum average temperature |

PLGASV |

cm3 |

Volume in pin plenum available to gas |

PLNAV |

cm3 |

Volume of sodium in plenum |

EXTRUS |

cm3 |

Volume of molten fuel extruded into the plenum |

WFTOT |

cm |

Total axial displacement of fuel |

WCTOT |

cm |

Total axial displacement of cladding |

F-TAVE |

K |

Average temperature of entire fuel column |

C-TAVE |

K |

Average temperature of cladding tube containing fuel |

Order |

Variable |

Unit |

Description |

|---|---|---|---|

1 |

TIME |

s |

Current time at which values of the variables are reported |

2 |

PCAVTY |

Pa |

Molten fuel cavity pressure |

3 |

CVGAST |

K |

Molten fuel cavity temperature |

4 |

AMELTF(NDZ) |

% |

Areal (radial) melt fraction for the top axial segment |

5 |

PPLEN |

Pa |

Pin plenum pressure |

6 |

PLGAST |

K |

Pin plenum temperature |

7 |

PFC(NDZ) |

Pa |

Fuel-cladding contact pressure at top axial segment |

8 |

SIGCM(NDZ) |

Pa |

Cladding average hoop stress in top axial segment |

9 |

EPSPTM(NDZ) |

Cladding average plastic hoop strain in top axial segment |

|

10 |

FRCPEN(NDZ) |

% |

Cladding eutectic penetration at top axial segment |

11 |

XLIFEF(NDZ) |

Cladding life fraction for top axial segment |

|

12 |

WCTOT |

cm |

Total cladding axial displacement |

13 |

WFTOT |

cm |

Total fuel axial displacement |

14 |

EXTRUL |

cm |

Length of molten fuel extruded into plenum |

15 |

FUELTL |

cm |

Total fuel elongation |

16 |

TCLADM(NDZ) |

K |

Average cladding temperature in top axial segment |

Footnotes