9.4. Solution Algorithm and Flow Charts¶

Figure 9.4.1 and Figure 9.4.2 show the MFUEL solution algorithm for pre-transient and transient analyses. MFUEL assumes the fuel pin can be modeled using a 1.5-dimensional approximation, therefore axial and radial loops are not explicitly shown in the algorithms. In each calculation step, MFUEL loops over each axial node independently and solves for the radial solution using a first-order approximation.

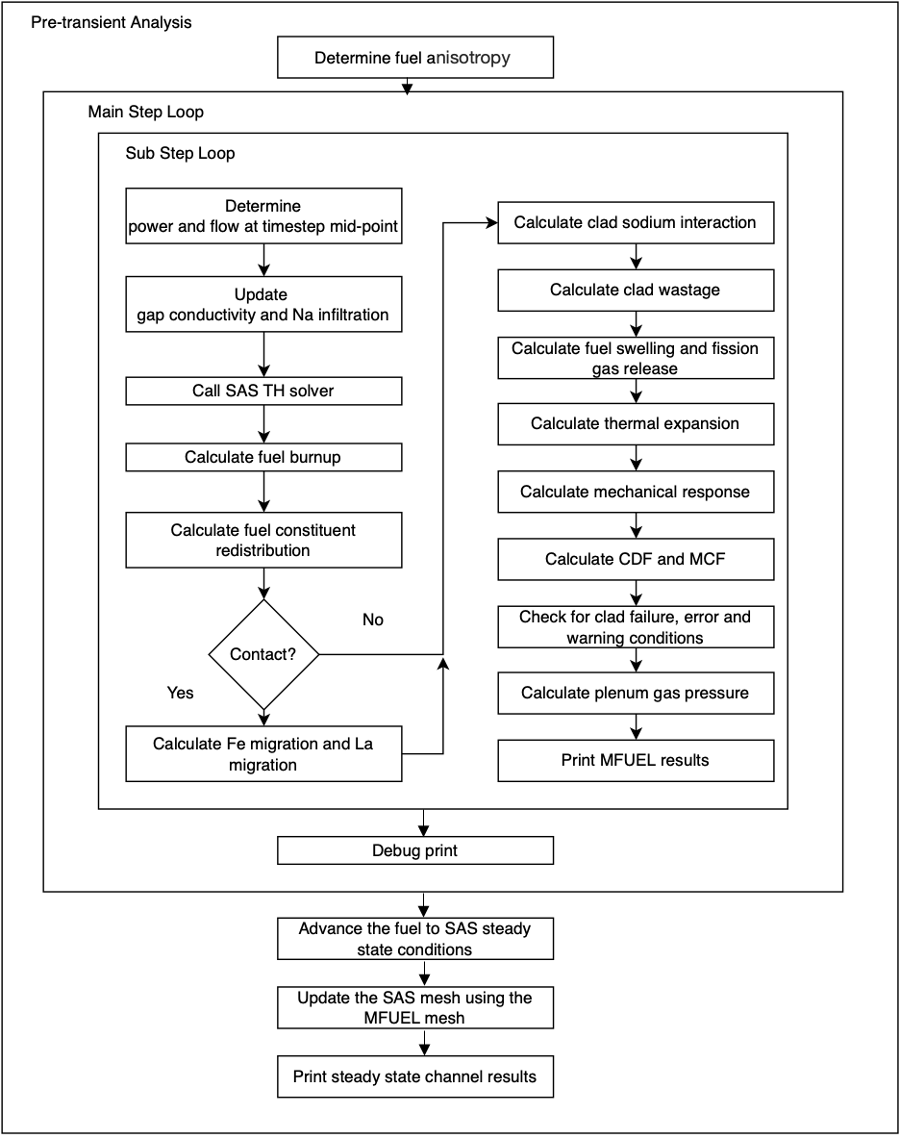

Pre-transient analysis is performed on a channel-by-channel basis during the SAS steady-state calculation. Based on user input, MFUEL solves for the changes to a fuel pin from the as-fabricated conditions to the start of the SAS transient simulation. As shown in Figure 9.4.1, the MFUEL pre-transient analysis loops over the user-defined irradiation history using substeps, as appropriate, to characterize the changes in the fuel pin. At the end of pre-transient characterization, MFUEL advances the fuel pin state to the match the user-defined SAS steady-state power and flow. With the new state, MFUEL updates the SAS axial and radial channel mesh and prints the steady-state solution.

For each substep of the pre-transient analysis, an average value for the user-provided power and flow is determined. The average power and flow is passed to the SAS thermal-hydraulic solver to determine fuel pin temperatures using the fuel pin composition and geometry at the start of the substep. Using the average power, the fuel pin burnup is incremented, along with the neutron fluence and dose to the cladding. Given the fuel temperature, redistribution of the fuel constituents is determined. If contact between the fuel and cladding has been predicted, iron and lanthanide migration is included. The coolant temperature is used to determine the clad and sodium corrosion interaction, which in addition to the iron and lanthanide migration, is used to determine the thickness of compromised, or wasted, cladding at the inner and outer surfaces. Fission gas production, migration, and release is simulated to determine the impact on fuel swelling. Given the state of swelling and the fuel pin temperatures, mechanical analysis is performed to determine the radial and axial elongation of the fuel pin and cladding. With the state of the fuel pin now known, the Cumulative Damage Fraction (CDF) and Mechanistic Clad Failure (MCF) of the clad are evaluated to determine the failure probability. The CDF and MCF value, along with the clad dose and wastage thickness are then checked to determine if warning or error messages need to be printed, providing users with an indication that a parameter has exceeded its validated range or clad failure has been predicted. Finally, the plenum pressure is updated based on the expansion of the fuel and cladding, the amount of fission gas released, and the relocation of in-pin sodium.

Figure 9.4.1 MFUEL Pre-transient Solution Algorithm¶

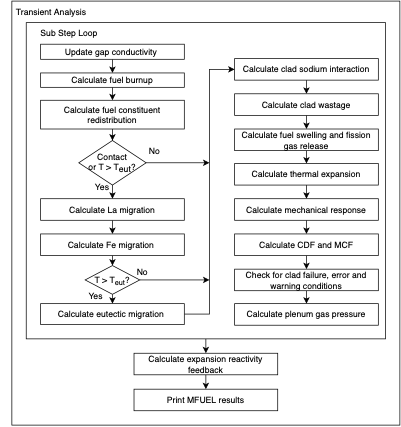

Similar to the MFUEL pre-transient analysis, the MFUEL transient analysis is performed on a channel-by-channel basis. For channels that utilize the MFUEL model, fuel pin conditions are updated at the end of each SAS heat transfer time step. The MFUEL transient analysis advances the state of the fuel pin using substeps, as shown in Figure 9.4.2. At the end of each main time step, MFUEL determines the reactivity contribution of the channel due to fuel and clad axial expansion.

For each sub-step of the transient analysis, the temperature and power of the fuel pin at the end of the main time step are used. SAS determines the temperature and power using the fuel pin geometry at the end of pre-transient and fuel pin composition at the start of main time step. Using the power, fuel pin burnup is incremented along with the neutron fluence and dose of the cladding. Given the fuel temperature, redistribution of the fuel constituents is determined. In the case of contact, lanthanide and iron migration are solved for. If the surface temperature of the fuel pin is high enough for eutectic formation to occur, iron migration is bypassed, and in its place the migration of the eutectic is determined. Corrosion due to sodium is tracked on the outside of the cladding. This internal and external wastage is used to determine the remaining thickness of the cladding for mechanical analyses. Fission gas production, migration, and release is simulated to determine the impact on fuel swelling. Given the state of swelling and the fuel pin temperature, mechanical analysis is performed to determine the radial and axial elongation of the fuel and cladding. With the state of the fuel pin now known, the CDF and MCF of the clad are evaluated to determine the failure probability. The CDF and MCF values, along with the clad dose and wastage thickness, are then checked to determine if warning or error messages need to be printed, providing users with an indication that a parameter has exceeded its validated range or clad failure has been predicted. Finally, the plenum pressure is updated based on the expansion of the fuel and cladding, the amount of fission gas released, and the relocation of in-pin sodium.

Figure 9.4.2 MFUEL Transient Solution Algorithm¶