13.4. Input-Output Description

A listing of CLAP-related input variables is given in Table 13.4.1 as an aid in preparing or modifying SAS input decks. Additionally, the input items on this list should be rechecked when problems are encountered in the running of SAS cases with cladding motion. This list contains all input items used directly by the following CLAP subroutines: TSCLD1, TSCLD2, SODFRC and DENSIT and, in addition, input items used to initiate CLAP and to calculate reactivity effects due to cladding motion (in subroutine FEEDBK).

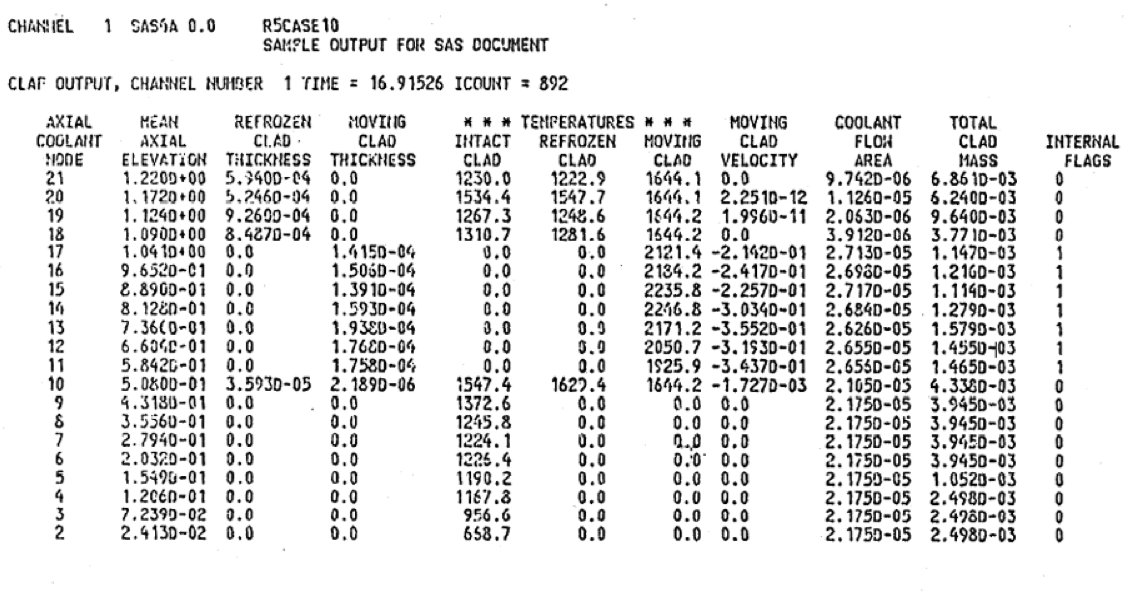

The CLAP output appears with both the main full printout and the boiling printout. A sample output is shown in Figure 13.4.1. The output labels are generally self-explanatory. The Fortran variable and units corresponding to each output item are given in Table 13.4.2.

Symbol |

Reference Eq. No. |

Reference |

Block |

Location |

Recommended Values |

|---|---|---|---|---|---|

Tref |

TR |

13 |

419 |

1700 K |

|

Tm |

— |

TESOL* |

13 |

810-812 |

1700 K [13-7] |

λo |

UEMELT |

13 |

816-818 |

2.703⨉105 J/kg [13-7] |

|

λo |

UEMELT |

13 |

816-818 |

2.703⨉105 J/kg [13-7] |

|

Cps |

CE |

13 |

1070-1072 |

690.1 J/kg K [13-7] |

|

ICLADV |

51 |

17 |

— |

||

ICLADB |

51 |

85 |

1 |

||

IDCLGO |

51 |

125 |

0 |

||

IDCLSP |

51 |

126 |

0 |

||

IDCLDE |

51 |

127 |

0 |

||

Wj |

CLADRA |

62 |

160-183 |

— |

|

ρos |

DENSS |

63 |

35 |

7.256⨉103 kg/m3† [13-7] |

|

C1,C2,C3 |

C1, C2, C3 |

64 |

3-5 |

Eq. (13.2-33) [13-8] |

|

AFRV,BFRV |

AFRV, BFRV |

64 |

168, 169 |

0.316, -0.25 |

|

ρoc |

DENS |

65 |

3 |

6.98⨉103 kg/m3† [13-7] |

|

β |

AE |

65 |

4 |

2.3⨉10-5/K† [13-7] |

|

C |

RHOCD |

65 |

5 |

8.3⨉10-5/K† [13-7] |

|

μm |

VISMC |

65 |

6 |

6.42⨉10-3 Pa-s [13-7] |

|

μT |

VISTR |

65 |

7 |

1⨉104 Pa-s [13-3] |

|

μs |

VISSC |

65 |

8 |

1⨉104 Pa-s [13-3] |

|

q |

XVISC |

65 |

9 |

0.5 |

|

bf |

CLADFR |

65 |

10 |

0.02 [13-3] |

|

(Re)break |

REBRK |

65 |

11 |

|

|

ε |

GMULTF |

65 |

12 |

75.0 [13-5] |

|

αcrit |

ALPHCR |

65 |

13 |

0.0 [13-5] |

|

(fps)o |

FPSO |

65 |

14 |

0.3s |

|

x |

EXPFPS |

65 |

15 |

3.0 |

|

θ |

CLSTHR |

65 |

17 |

1.0 |

|

a |

AVISC |

65 |

20 |

5492 K [13-7] |

|

cpc |

CPC |

65 |

21 |

621.7 J/kg K† [13-7] |

*Orginally TME, but TME is now set equal to the solidus temperature TESOL.

†Evaluated at the melting temperature of 1700 K.

Item |

Symbol |

FORTRAN Variable |

Units |

|---|---|---|---|

CLAP Time Step Count |

n |

ICOUNT |

— |

Axial Coolant Mode |

j |

J |

— |

Main Axial (Nodal) Elevation |

zm,j |

ZFM |

m |

Refrozen Cladding Thickness |

2Δrs |

RCLAD1 |

m |

Moving Cladding Thickness |

2Δrc |

TCLAD1 |

m |

Intact Cladding Temperature |

Ti |

TCLAV |

K |

Refrozen Cladding Temperature |

Ts |

TEMFS1 |

K |

Moving Cladding Temperature |

Tc |

TEMMC1 |

K |

Moving Cladding Velocity |

Vc |

CVEL1 |

m/s |

Coolant Flow Area |

Av |

AREAC1 |

m2 |

Internal Flag (=1 in molten zone, =0 otherwise) |

LVEL |

— |

Figure 13.4.1 Sample CLAP Output