3.7. Fuel Pin Heat-transfer After Pin Disruption or Relocation of Fuel or Cladding¶

The preceding sections describe fuel pin heat transfer with intact fuel pins and no relocation of fuel of cladding. After pin disruption or the relocation of fuel or cladding, the heat transfer calculations are modified. The modifications after the start of in-pin fuel relocation in the PINACLE module are described in Chapter 15. The modification after the start of cladding melting and relocation in the CLAP module are described in Chapter 13. The modifications after pin disruption are described in Section 3.7.1 below and in Chapter 14 and Chapter 16.

3.7.1. Fuel-pin Heat Transfer After Pin Disruption in PLUTO2 or LEVITATE¶

When PLUTO2 or LEVITATE is active, the PLHTR subroutine calculates the heat conduction in all solid fuel (including axial blankets) and also in the cladding which is in contact with the lower and upper coolant slugs. The heat conduction calculation of the cladding in the interaction region, which is between the lower and upper coolant slug, (see Fig. 14.1-4) is performed in the PLUTO2 or LEVITATE modules (see Section 14.5.2 and Section 16.5.7) using a shorter time step than the PLHTR calculation.

Along the interaction region, the heat flow rate from the cladding inner surface to the fuel outer surface is calculated in PLUTO2 or LEVITATE assuming a constant gap conductance of the value in existence at the time of initiation. The PLUTO2 or LEVITATE calculated heat flow rates are integrated over a PLHTR time step in order to provide PLHTR with the total heat added during a heat-transfer time step. Outside the interacting region the heat flow rate between the liquid sodium flow and the cladding outer surface is calculated in the PLCOOL subroutine of PLUTO2. The latter subroutine mainly determines the liquid sodium temperatures in the coolant slugs. It uses the same time step as the PLHTR subroutine.

The temperature calculations in the molten fuel cavity in the pins are performed by PLUTO2 or LEVITATE and are part of the in-pin fuel motion calculation in these modules. The heat flow rates from each molten cavity node to the surrounding sold fuel are also calculated in PLUTO2 or LEVITATE. Since the time steps of the latter modules are shorter than the PLHTR time steps, the PLUTO2 or LEVITATE heat flow rates have to be integrated over the whole heat-transfer time step, because the total heat transferred to the cavity wall during a heat-transfer time step is required by PLHTR.

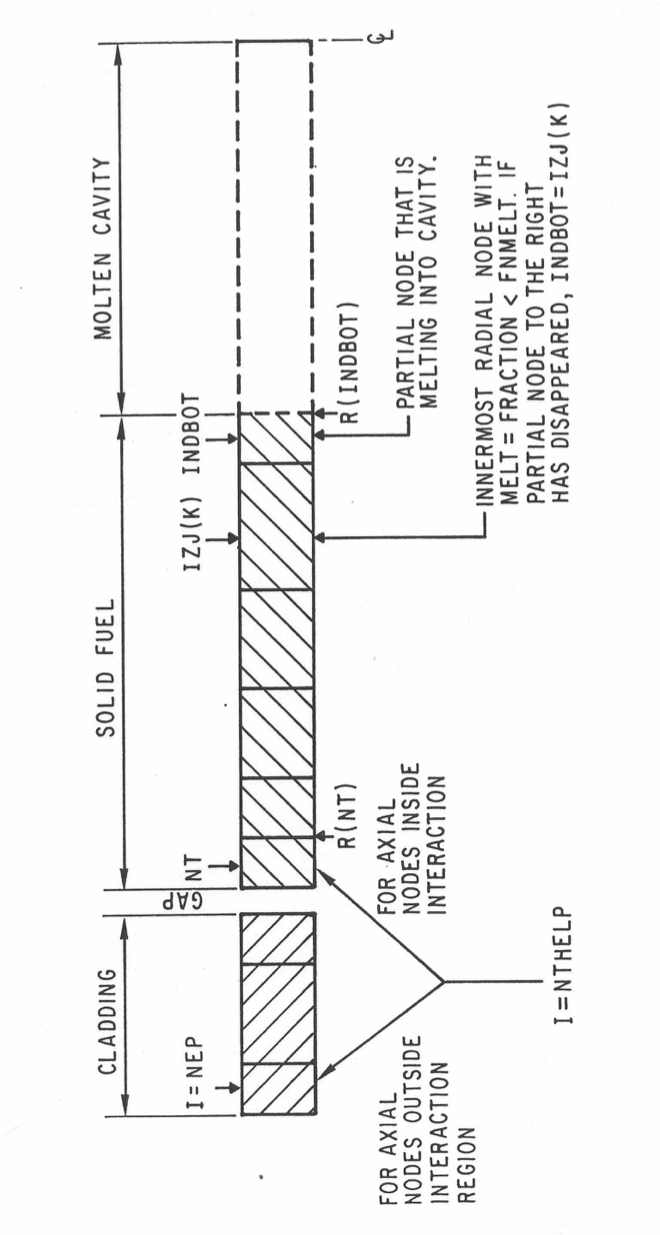

The initial configuration of the molten pin cavity at the time of pin failure is determined in the PLUTO2 and LEVITATE initialization routines PLINPT and PLSET (see Section 14.2.2). PLINPT initializes the integer array IXJ(K) for each axial node K with the index of the innermost radial fuel node whose melt fraction has not yet exceeded the input value FNMELT. This array IZJ(K) thus determines the initial molten cavity configuration.

When PLUTO2 or LEDVITATE are active, additional fuel can melt into the cavity and thereby enlarge it. The integer array IZJ(K) is updated for each axial node K whenever another radial node exceeds the input value FNMELT. However, such a radial node is only gradually added to the molten cavity (see Eqs. 14.2-10 to 14.2-12). The heat conduction calculation in PLHTR includes this partial node.

Figure 3.7.1 shows the radial grid used in PLHTR. The heat conduction calculation covers the radial region from I = INDBOT to I = NTHELP. The latter can be the outermost radial fuel node (for axial nodes in the interaction region) or the outer cladding node (for axial nodes outside the interaction region). Temperatures and heat sources are defined at the midpoints of the grid in Figure 3.7.1.

PLHTR is a modified version of the TSHTRV subroutine that calculates the fuel-pin heat transfer during coolant boiling and the reader is referred to Section 3.5 for a detailed presentation of the equations. One of the main differences is that the conduction calculation is done only in the solid fuel region and in the cladding outside the interaction region. This is achieved by having the calculational loops go from I = INDBOT to I = NTHELP (see Fig. 14.2-1) and by adding or subtracting the integrated heat flux to or from the solid fuel nodes at the boundaries in the form of heat sources or sinks, respectively. The integrated heat flux at the outer pin boundary is obtained from

Figure 3.7.1 Radial Grid for the PLHTR Calculation¶

the array HFPICL, calculated in the PLUTO routine PLMISE or in the LEVITATE routine LESDEN. The integrated heat flux at the cavity boundary is obtained from the array HFCAWA; calculated in the PLUTO routine PC1PIN or the LVITATE routine LE1PIN. Moreover, the heat conduction terms at the fuel surface, which are necessary in the TSHTRV calculation, had to be set to zero. This meant setting the term BETA (NTHELP) in Eq. 3.3-48 to zero and ignoring all equations related to the cladding in Eq. 3.3-48.