5.4.7. RVACS/RACS Models

Three RVACS (Reactor Vessel Auxiliary Cooling System) or RACS (Reactor Air Cooling System) Models have been included in SAS4A/SASSYS‑1: a simple model in which the user supplies the relevant information for the outside of the reactor vessel wall, a more detailed model in which air temperatures and flow rates are calculated by SAS, and a coupled model where an external code provides the relevant information for the region outside of the reactor vessel wall. The reactor coolant treatment and the representation of the reactor vessel wall are the same in all models. The vessel wall is represented by a combination of compressible volume walls and the walls of pipes and annular elements. The component-to-component heat transfer capability described in Section 5.4.6 above is used to remove heat from the reactor vessel walls, and the three models are used to set Tsnk, Hsnk, and Asnk, for the wall.

The input required for each of the RVACS models is described below.

5.4.7.1. Simple RVACS Model

For the simple model the representation of the RVACS stops at the reactor vessel wall. The user supplies a single air temperature and a table of effective heat transfer coefficient vs. vessel wall temperature. For each axial node in the reactor vessel wall, the code then sets the sink temperature, Tsnk, to the air temperature. The sink heat transfer coefficient, hsnk, is re-calculated each time step based on the current vessel wall temperature at the node.

5.4.7.2. Detailed Air Side Model

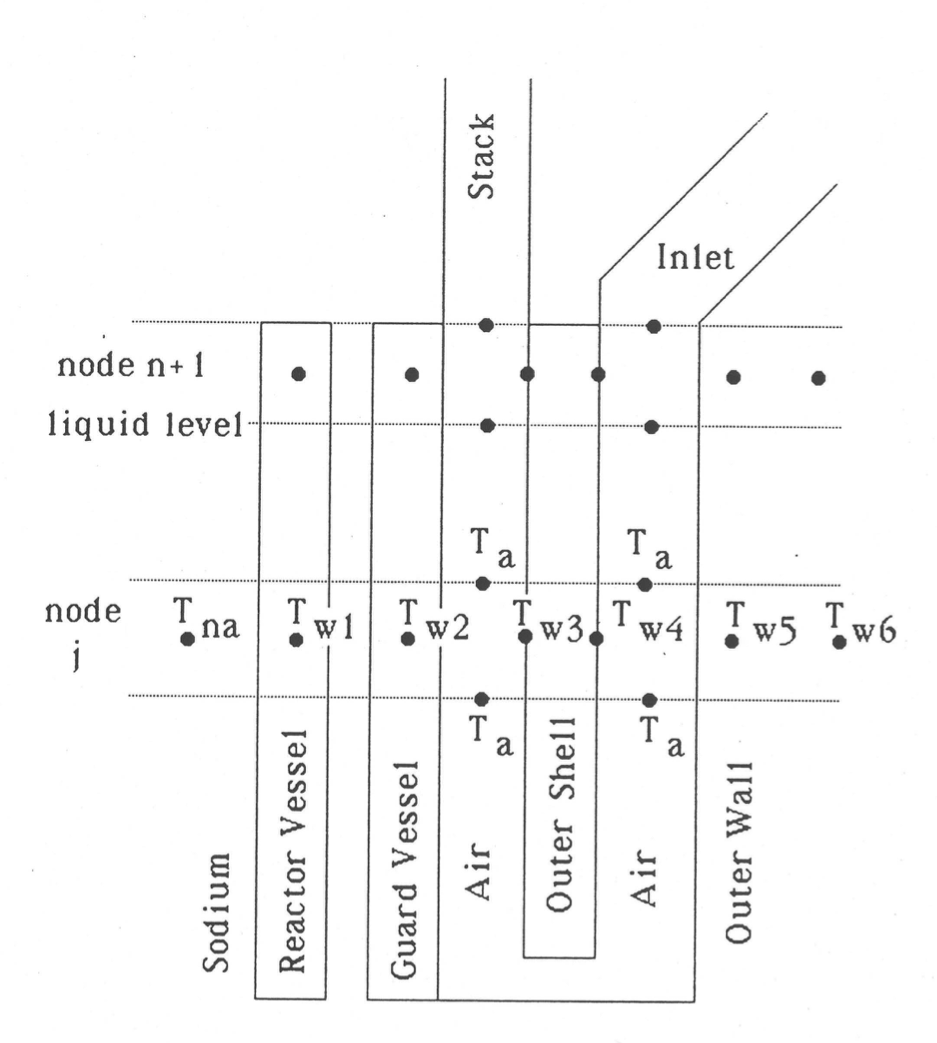

Figure 5.4.8 shows the general RVACS model and noding scheme. Wall temperature nodes are used for the reactor vessel, guard vessel, finned shell (inside and outside), outer wall, and a constant temperature deep in the concrete or the ground. Air nodes are included for the down-comer and for the up-flow section. An air inlet section and an outlet stack are also included. Either vertical or non-vertical sections of vessel wall can be treated.

The reactor vessel wall can be made up of a number of SAS4A/SASSYS‑1 components, including a hot pool wall, a cold pool wall, a pipe wall, or an annular flow element wall. The annular flow element is a new type of liquid flow element that has recently been added to SAS4A/SASSYS‑1, mainly for modeling the RVACS and for modeling multi-dimensional effects in pools.

Both radiative and convective heat transfer from the reactor vessel to the guard vessel are modeled. Radiation from the guard vessel to the finned shell as well as convective heat transfer to air from the guard vessel and the finned shell are treated.

The finned shell is assumed to be insulated, but less-than-perfect insulation can be treated. Temperatures on both sides of the insulation are calculated. Heat transfer from the inside of the to the outside, and from the outside of the finned shell to the incoming air, is treated. Radiation from the finned shell to be outer wall is treated as well as convective heat transfer from the outer wall to the incoming air. Also, conduction from the outer wall to a constant temperature node deep in the concrete or in the ground is handled. With perfect insulation on the finned shell and little heat transfer into the concrete, the calculation of air and wall temperatures on the down-comer side would be unnecessary; the air temperature at the bottom of the up-flow side could be set to the outside air inlet temperature. The model with heat transfer to the incoming air allows consideration of the impact on RVACS-RACS performance of limited insulation between the downcomer and the up-flow side.

As indicated in Figure 5.4.8, one axial node is included above the liquid level in the vessel. This node is included to account for heat transfer through the finned shell between incoming and outgoing air. For this node, the heat transfer coefficient between the reactor vessel and the guard vessel is set to zero.

Figure 5.4.8 SAS4A/SASSYS‑1 Model of an RVACS/RACS System.

5.4.7.2.1. Basic Equations

Wall Temperatures

Reactor Vessel

The basic equation for the reactor vessel wall temperature is

where

mw1 = reactor vessel wall mass per unit length

Cw1 = reactor vessel specific heat

Tw1 = reactor vessel wall temperature

t = time

hNw1 = heat transfer coefficient between the sodium inside the vessel and the vessel wall

ANw1 = inner perimeter, or heat transfer area per unit length, of the vessel wall

TN = sodium temperature

hw12 = heat transfer coefficient between the reactor vessel and the guard vessel, including both radiation and convection terms

Aw12 = outer perimeter of the reactor vessel, PERVAC

Tw12 = guard vessel temperature

Guard Vessel

where

(mC)w2 = heat capacity per unit length of the guard vessel, GVMC

FNT = thermal inertia inverse scaling factor

hw23 = radiation heat transfer coefficient between the guard vessel and the finned shell

Aw23 = outer perimeter of the guard vessel, PERGVO

Tw3 = temperature of the finned shell inner node

Ta1 = air temperature in the up-flow section

hw2a = heat transfer coefficient between the guard vessel and air

Aw2a = perimeter between the guard vessel and

the air, PERGV

FNT varies depending on the stage of the simulation

where FINVNT is the user provided inverse scaling factor, FINVNT. The thermal inertia inverse scaling factor allows the detailed RVACS component to

approach a steady state faster during the null transient simulation.

Finned shell, Inner Node

(mC)w3 = heat capacity per unit length of the inside of the finned

shell, FSMCI

Tw3 = finned shell inner node temperature

hw34 = heat transfer coefficient between the inside

and outside of the finned shell, HFSRV

Aw34 = perimeter of the finned shell, PERFSO

hw3a = heat transfer coefficient between the finned shell and the upflowing air

Aw3a = perimeter between the finned shell and the upflowing

air, PERFS

Tw4 = finned shell outer node temperature

Finned Shell, Outer Node

(mC)w4 = heat capacity per unit length of the outside of the finned

shell, FSMCO

Tw5 = concrete wall inner node temperature

hw45 = heat transfer coefficient between the finned shell and the concrete

Aw45 = finned shell outer perimeter, PERFSO

Ta2 = temperature of the down-flowing air

hw4a = heat transfer coefficient between the finned shell outer surface and the down-flowing air

Aw4a = perimeter between the finned shell outer

surface and the down-flowing air, PERFSO

Cavity Wall, Inner Node

(mC)w5 = heat capacity per unit length of the inside of the cavity

wall, CRMCI

Tw6 = constant temperature deep in the concrete or ground

hw56 = heat transfer coefficient between the cavity wall surface node and the constant temperature heat sink

Aw56 = cavity wall perimeter, PERFSO

hw5a = heat transfer coefficient from the cavity wall to the down-flowing air

Air Temperature

The air is treated with a quasi-static approximation, neglecting the time derivative of the air temperature and density.

Up-Flowing Air Between the Guard Vessel and the Finned Shell

where

wa = air mass flow rate, kg/sec.

Ca = air specific heat

Down-Flowing Air Between the Finned Shell and the Concrete Wall

Air Flow Rate

As shown in Figure 5.4.8, the air flow path is modeled as an inlet section, a down-flow section between the outer surface of the finned shell and the cavity wall, an up-flow section between the guard vessel and the inner surface of the finned shell, and an outlet stack. The air temperature in the inlet section is assumed to be equal to the external air temperature, which the user can define as either constant or varying with time. In the stack, the air temperature is assumed to equal the value at the outlet from the guard vessel-finned shell region. Between the inlet section and the stack, the air temperature is calculated on a node-by-node basis.

The inertia of the air is ignored, and the air flow rate is calculated by balancing the air gravity head with the loss terms.

The gravity head, Δpgr, is calculated as

where

g = acceleration of gravity, GRAVITY

ρin = air density in the inlet section

ρstack = air density in the stack

¯ρa1(j) = average air density in node j for upflow air

Δzj = height of node j

Δzin = elevation gain in the inlet, XLAIRV

Δzstack = elevation gain if the stack, XLAORV

zst = elevation of the stack outlet

and

zin = inlet elevation

The loss term, Δploss, is calculated as

where

wa = air flow rate

Aa,i = air flow area in node i

ρa,i = air density in node i

f = friction factor

kor = inlet orifice coefficient

Li = length of the node i

Dh,i = hydraulic diameter of node i

The summation is over the inlet section (i=1), the stack, and each of the nodes between.

The friction factor is calculated as

where

μa = viscosity

Afr = user-supplied turbulent friction factor coefficient, AFRTRV,

b = user-supplied turbulent friction factor exponent, BFRTRV, and

Afl = user-supplied laminar friction factor coefficient, AFRLRV

The value of Ret, the Reynolds number for the transition from

turbulent to laminar, REYTRV, is calculated by the code to make the friction

factor continuous at the transition point.

Or

Heat Transfer Coefficients

Reactor Vessel (RV) to Guard Vessel (GV)

The approximation is made that Rw1 and Rw2 are lumped in with hcv12, so

where

and

hcv12 = user-supplied convective heat transfer

coefficient, RV to GV, HGASRV

εRV = emissivity of the reactor vessel wall, EPSRV

εGVI = emissivity of the guard vessel inner surface, EPSGV

σ = Stefan-Boltzmann Constant, SIGSTB

GRV = thickness of the reactor vessel

GGV = thickness of the guard vessel

kGV = thermal conductivity of guard vessel

kRV = thermal conductivity of the reactor vessel

GV to Finned Shell (FS)

Rw2 is neglected, so

εGVO = emissivity of the guard vessel outer surface, EPSGVO

εFSI = emissivity of the finned shell inner surface, EPSFSI

Finned Shell

hw34 = a constant, user-supplied, conduction

coefficient, HFSRV

Outer Wall

or

where

Rw5 = thermal resistance in the outer wall to the

location of Tw5, RW5RV

hw56 = a constant, user supplied, conduction

coefficient, HCONRV

εFSO = emissivity of the finned shell outer surface, EPSFS

εOW = emissivity of the outer wall, EPSOW

Air

again Rw2a is neglected, so

where the air heat transfer coefficient is

ka = air thermal conductivity

Dha = hydraulic diameter between the guard vessel and the finned shell or between the finned shell and the outer wall

Nu = Nusselt number

wa = air flow rate

Aa = air flow area, AIRARV or AIRAR2

μa = air viscosity

Pr = Prandtl number

C1, C2, C3 = user supplied correlation

coefficients, C1RV, C2RV, C3RV

C1∼.023

C2∼0.8

C3∼3−8

Ret = Reynolds number for transition from turbulent to laminar heat transfer

Also,

or

Air Properties

Correlations used for air thermal properties are:

Density

where

T = air temperature (K)

Specific Heat

Prandtl Number:

Viscosity

Thermal Conductivity:

These correlations agree with the tables of dry air properties on page 522 of Ref. 5-6 over the range from 255.4 K (0°F) to 1088.7 K (1500°F) to within .2% for ρa, .34% for Cpa, .03% for Pr0.4, 1% for μ, .4% for μ0.2, and 2.7% for k.

5.4.7.2.2. Finite Difference Solution

Finite Difference Equations

Reactor Vessel

The coupling between the RVACS/RACS model and the rest of SAS4A/SASSYS‑1 takes place at the reactor vessel wall. Heat transfer from the vessel wall to the guard vessel is treated using the component-to-component heat transfer capability of the code. Eq. (5.4-106) becomes

where hsnk, Asnk, and Tsnk are the sink heat transfer coefficient, area, and temperature used in the component-to-component heat transfer treatment. At the beginning of each time step these values are re-set as

where PRVj is the user-defined RV perimeter and Pcomponentj is the perimeter of the primary system component (element or CV) which RVACS is coupled to, for node j. The vessel wall is modeled as a combination of compressible volume walls, pipe walls, and annular element walls. The thermal treatments for these components solve Eq. (5.4-148).

Determination of Pcomponentj in Eq. (5.4-149) is described by Table 5.4.16, below. It should be noted that all parameters used to calculate Pcomponentj are obtained directly from user input.

Coupled Component |

Pcomponentj |

|---|---|

CV |

PRVj |

Pipe |

4ADh |

Annular Element |

Psecondwall |

Air Temperature

A treatment similar to the log-mean temperature difference treatment is used for the air. Fully implicit time differencing is used in the sense that the values used for Tw2 and Tw3 in Eq. (5.4-112) are the values at the end of the time step. Also, it is assumed that Tw2 and Tw3 are constant across a node. For node j, which extends from zj to zj+1, the solution of Eq. (5.4-112) then becomes

where

and

The heat flow from the guard vessel to the air in node j is then

where

Combining Eq. (5.4-152) and Eq. (5.4-158) gives

The wall temperatures are solved for simultaneously with the air temperatures, so one uses

and

where the time step size is Δt. Then Eq. (5.4-160) has the form

where

and

Similarly,

and

where

and

Guard Vessel

Fully implicit time differencing is used for the wall temperature. Eq. (5.4-107) becomes

or

where

and

Finned Shell, Inner Node

Eq. (5.4-109) becomes

where

Finned Shell, Outer Node

Eq. (5.4-110) becomes

where

and

Cavity Wall, Inner Node

Eq. (5.4-111) becomes

where

and

Cavity Wall, Outer Node

The sink temperature is assumed to be constant:

Tw6 = constant

Solution of Finite Difference Equations

Simultaneous Solution of Equations

Down-Flowing Air, Transient Solution

The finned shell outer node and cavity wall inner node temperatures are solved for simultaneously, assuming the finned shell inner node temperature is constant. Solving Eq. (5.4-192) and Eq. (5.4-197) simultaneously gives

Then Eq. (5.4-197) can be solved for ΔTw5.

Up-Flowing Air, Transient Solution

The guard vessel and finned shell inner node temperatures are solved for simultaneously, assuming the finned shell outer node temperature is constant. Solving Eq. (5.4-183) and Eq. (5.4-187) simultaneously gives

Then Eq. (5.4-183) is solved for ΔTw3.

Solution Method

No steady-state solution for the RVACS/RACS has been coded; the initial steady-state results are obtained by running a null transient. First the air and wall temperatures are set to the air inlet temperature. Then the null transient is run to set the initial steady-state temperatures and flow rate. Finally the regular transient is run. During the null transient the core channel calculations are bypassed, the sodium flow rates are held constant, the inlet and outlet plenum temperatures are held constant, and temperatures and air flow rates are calculated for the rest of the sodium and the RVACS/RACS. The routines used in the null transient are the same as those used in the regular transient.

An iteration on air flow rate is used in the transient solution. An air flow rate is assumed, temperatures are calculated for this air flow rate, the air gravity head is calculated, and the air pressure loss is calculated. Then the gravity head is compared with the pressure loss; and if the two do not balance, another air flow rate is tried. The iteration on air flow rate continues until a balance is achieved. The temperature calculation starts at the inlet and works down the inlet side then back up the air up-flow side. The heat transfer coefficients and the heat transfer across the finned shell are calculated based on conditions at the beginning of the time step. The rest of the calculation is fully implicit in its time differencing.

5.4.7.3. Coupled RVACS Model

For the coupled model, the representation of the RVACS stops at the Reactor Vessel (RV) wall. At the end of each PRIMAR-4 time step, SAS4A/SASSYS‑1 transfers the temperate of each axial node in the RV wall to an external code. The external code is expected to provide a sink temperature, Tsnk, and a heat transfer coefficient, hsnk for each node. Tsnk and hsnk are assumed to remain constant during the subsequent PRIMAR-4 time step, after which it will be updated again.

Due to the uniqueness of the SAS4A/SASSYS‑1 null transient, the coupled RVACS model has been developed such that it can:

If a user selects for the coupled RVACS model to participate in the null transient, the external code must be capable of handling the reset of the simulation elapsed time. The simulation elapsed time will reset when SAS4A/SASSYS‑1 transitions from a null transient to the first transient calculation step.

Note

When IRVOPT < -1000, input for the simple RVACS model must be provided to support the null transient calculation.

The coupled RVACS model relies on ZMQ for data transfer between SAS4A/SASSYS‑1 and

the external code. ZMQ is a C++ asynchronous messaging library that allows for

data transfer interfaces that are simple to create and flexible [5-9].

At the beginning of a SAS4A/SASSYS‑1 calculation containing a coupled RVACS model,

SAS will create a ZMQ_PAIR socket bound to a random (ephemeral) TCP port.

If the binding is successful, the RVACS coupling service is established, and a message is written to the SAS4A/SASSYS‑1 log file.

If the binding fails, an error is reported in the SAS4A/SASSYS‑1 output file.

To determine the RVACS service port, an external code must first connect to the SAS ‘’Harbor Master’’ on port 60439

using a ZMQ_REQ socket and send a lookup request to determine which port the RVACS service is bound to.

This process typically occurs at the start of the null transient, or in the case of a restart,

at the start of the first transient calculation. Once the port is identified, the external

code must connect to that port using a ZMQ_PAIR socket for RVACS communications.

At the end of each PRIMAR-4 time step SAS4A/SASSYS‑1 will send a multi-part ZMQ message containing the following:

Variable |

Description |

Type |

|---|---|---|

|

The number of nodes representing the RV wall. |

|

|

A flag indicating if SAS4A/SASSYS‑1 is computing a null transient step, |

|

|

A flag indicating if SAS4A/SASSYS‑1 saved a restart after the previous time step. |

|

|

The time at the start of the PRIMAR-4 time step (seconds). |

|

|

The size of the PRIMAR4 time step (seconds). |

|

|

An array of size |

|

|

An array of size |

|

SAS4A/SASSYS‑1 then reads in a data package containing:

Variable |

Description |

Type |

|---|---|---|

|

The number of nodes representing the RV wall. |

|

|

An array of size |

|

|

An array of size |

|

SAS4A/SASSYS‑1 will wait at the read stage until the external code has sent a response.

If the external code provides data of the wrong shape, i.e. the values of nMesh are not consistent, or sends an incomplete response,

SAS4A/SASSYS‑1 will print an error message and exit.

An example Coupled RVACS routine is shown below. The example returns a constant heat sink temperature and heat transfer coefficient for each RV node until the time reaches 100 seconds.

#include <zmq.h> // See https://github.com/zeromq/libzmq

#include <iostream>

#include <string.h>

#include <assert.h>

#include <unistd.h>

struct Service{

char tag[4];

int id;

};

int main (void)

{

// Set up scalar variables

int nMesh, isNull, rc, port;

int saved;

double time, dt;

Service serv, reply;

char buff[25];

printf ("Connecting to SAS…\n");

void *context = zmq_ctx_new(); // Create a new context

void *request = zmq_socket(context, ZMQ_REQ); // Create a socket on that context

zmq_connect(request, "tcp://localhost:60439"); // Connect the socket to TCP:60439

// Ask SAS what port RVACS is communicating on

std::strncpy(serv.tag,"RVAC",4);

serv.id = 0;

for(;;) {

// Ask to connect to RVACS

assert(zmq_send(request, &serv, sizeof(serv), 0) > 0);

printf("Sent\n");

// Recieve the reply from the harbor

assert(zmq_recv(request, &reply, sizeof(reply), 0) > 0);

printf("Recieved\n");

if (strncmp(reply.tag,"PORT",4) == 0) {

port = reply.id; // If a port was revieved set the port number

break;

} else if (strncmp(reply.tag,"WAIT",4) == 0) {

usleep(1 * 1000);

// usleep takes sleep time in us (1 millionth of a second)

} else {

return -1;

}

}

zmq_close(request);

assert(port > 0);

snprintf(buff,25,"tcp://localhost:%d",port);

request = zmq_socket(context, ZMQ_PAIR); // Create a socket on that context

zmq_connect(request, buff); // Connect the socket to the new port

printf("Connected\n");

// Receive the number of nodes on the RVACS wall

assert(zmq_recv(request, &nMesh, sizeof(int), 0) > 0);

assert(nMesh > 0);

double Z[nMesh], T1[nMesh], T2[nMesh], h12[nMesh];

// Receive the null transient information

assert(zmq_recv(request, &isNull, sizeof(int), 0) > 0);

// Receive the save flag

assert(zmq_recv(request, &saved, sizeof(int), 0) > 0);

// Receive the start time

assert(zmq_recv(request, &time, sizeof(double), 0) > 0);

// Receive the timestep

assert(zmq_recv(request, &dt, sizeof(double), 0) > 0);

// Receive the axial mesh

assert(zmq_recv(request, &Z, sizeof(Z), 0) > 0);

// Receive the RV temperature

assert(zmq_recv(request, &T1, sizeof(T1), 0) > 0);

// Set the Sink temperature and heat transfer coefficients to

// constant values

for ( int i = 0; i < nMesh; i++ ) {

T2[i] = 560.0;

h12[i] = 166.953;

}

// Send back the number of incoming nodes

assert(zmq_send(request, &nMesh, sizeof(int), ZMQ_SNDMORE) > 0);

// Send back the sink temperature

assert(zmq_send(request, &T2, sizeof(T2), ZMQ_SNDMORE) > 0);

// Send back the sink heat transfer coefficient

assert(zmq_send(request, &h12, sizeof(h12), 0) > 0);

// Continue communicating with SAS until the SAS time reaches 100.

while(time+dt<100.-1E-6) {

assert(zmq_recv(request, &nMesh, sizeof(int), 0) > 0);

assert(zmq_recv(request, &isNull, sizeof(int), 0) > 0);

assert(zmq_recv(request, &saved, sizeof(int), 0) > 0);

assert(zmq_recv(request, &time, sizeof(double), 0) > 0);

assert(zmq_recv(request, &dt, sizeof(double), 0) > 0);

assert(zmq_recv(request, &Z, sizeof(Z), 0) > 0);

assert(zmq_recv(request, &T1, sizeof(T1), 0) > 0);

assert(zmq_send(request, &nMesh, sizeof(int), ZMQ_SNDMORE) > 0);

assert(zmq_send(request, &T2, sizeof(T2), ZMQ_SNDMORE) > 0);

assert(zmq_send(request, &h12, sizeof(h12), 0) > 0);

printf ("Time: %f\n",time+dt);

};

// Close the socket

zmq_close(request);

// Destroy the context

zmq_ctx_destroy(context);

printf ("Done!\n");

return 0;

}

5.4.7.4. RVACS Input Description

Variable |

Description |

|---|---|

Number of sections in the RVACS model. |

|

RVACS model selection |

|

Element number or -ICV, starting at the bottom and going up. |

|

Number of nodes in this section. |

|

Debug parameter for RVACS |

Variable |

Description |

|---|---|

Function block ID for RVACS air inlet temperature as a function of time if > 0. If = 0 |

|

Function block ID for RVACS air inlet orifice coefficient as a function of time if > 0. If = 0, |

Variable |

Range |

Description |

|---|---|---|

>=0.0 |

Length of RVACS section. |

|

>=0.0 <=1.0 |

Slope of RVACS section. |

|

>0.0 |

Reactor vessel perimeter. |

|

- |

The bottom elevation of RVACS. |

Variable |

Range |

Description |

|---|---|---|

!=0.0 |

Table of H vs T. |

|

!=0.0 |

Reactor vessel temperature for RVHTAB table. |

|

!=0.0 |

Air inlet temperature. Ignored if |

Variable |

Range |

Description |

|---|---|---|

>0.0 |

Perimeter of the guard vessel for convective heat transfer. |

|

>0.0 |

Perimeter of the guard vessel for radiative heat transfer. |

|

>0.0 |

Perimeter of the inner finned shell for convective heat transfer. |

|

>0.0 |

Perimeter of the outer finned shell and outer wall for convective and radiative heat transfer. |

|

>0.0 |

Flow area between the guard vessel and finned shell. |

|

>0.0 |

Flow area between the finned shell and the outer wall |

|

>=0.0 |

Emissivity of the reactor vessel. |

|

>=0.0 |

Emissivity of the inner guard vessel wall. |

|

>=0.0 |

Emissivity of the outer guard vessel wall. |

|

>=0.0 |

Emissivity of the inner finned shell wall. |

|

>=0.0 |

Emissivity of the outer finned shell wall. |

|

>=0.0 |

Emissivity of the outer wall. |

|

>0.0 |

Heat capacity of the guard vessel wall per unit length. |

|

>0.0 |

Heat capacity of the finned shell inner node wall per unit length. |

|

>0.0 |

Heat capacity of the finned shell outer node wall per unit length. |

|

>0.0 |

Heat capacity of the outer wall inner node wall per unit length. |

|

>0.0 |

Heat capacity of the outer wall outer node wall per unit length. |

|

>=0.0 |

Heat transfer coefficient between the reactor vessel and guard vessel. Can include convective and conductive heat transfer. |

|

>=0.0 |

Heat transfer coefficient between the inner and outer finned shell nodes. |

|

>0.0 |

Thermal resistance of the outer wall inner node. |

|

>=0.0 |

Heat transfer coefficient of the outer wall outer node. |

|

>0.0 |

Temperature of the outer wall outer node. |

|

>0.0 |

Air inlet temperature. |

|

>0.0 |

Length of the inlet stack. |

|

>0.0 |

Hydraulic diameter of the inlet stack. |

|

>0.0 |

Flow area of the inlet stack. |

|

>0.0 |

Length of the outlet stack. |

|

>0.0 |

Hydraulic diameter of the outlet stack. |

|

>0.0 |

Flow area of the outlet stack. |

|

>0.0 |

First heat transfer correlation coefficient for air in RVACS |

|

- |

Second heat transfer correlation coefficient for air in RVACS |

|

>0.0 |

Third heat transfer correlation coefficient for air in RVACS |

|

>=0.0 |

Reynolds number at which laminar flow transitions to turbulent flow. This input is overwritten according to Eq. (5.4-120) |

|

>=0.0 |

Stefan-Boltzmann constant. |

|

>=0.0 |

First turbulent friction factor parameter. |

|

- |

Second turbulent friction factor parameter. |

|

>=0.0 |

Laminar friction factor parameter. |

|

>=0.0 |

Inlet orifice coefficient. Ignored if |

|

>0.0 |

Length of upper reactor vessel node. |

|

>0.0 |

Heat capacity of the upper guard vessel node per unit length. |

|

>0.0 |

Heat capacity of the upper finned shell node per unit length. |

|

>0.0 |

Flow area of the upper node. |

|

>=0.0 |

Inverse scaling factor for structure thermal inertia during null transient. Default: 10.0 |